Description

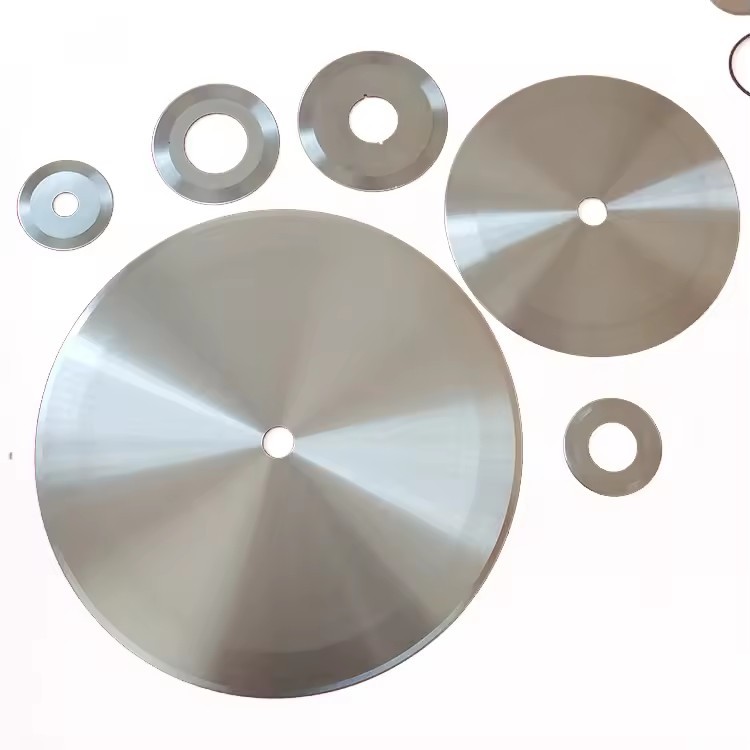

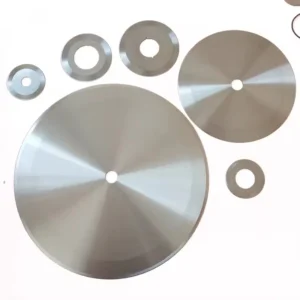

Circular slitter blades are cutting tools with a circular shape that rotate to slice through materials. These blades are typically mounted on a machine or assembly line and rotate at high speeds to efficiently cut through a wide range of materials. The blade's edge is extremely sharp and designed to maintain its cutting performance over time, even with continuous use.

Circular slitter blades are often adjustable, allowing for precise control over the cutting width and depth. This adjustability makes them suitable for various applications, from slicing thin films to thicker materials. The blades are also designed to minimize friction and heat generation during the cutting process, ensuring a smooth and efficient operation

Advantages of Circular Slitter Blades

Precision cutting

Circular slitter blades are designed to make precise cuts in the metal coils, resulting in high-quality strips that are uniform in width and thickness.

High efficiency

Circular slitter blades are capable of cutting large volumes of metal coils quickly and efficiently, enabling manufacturers to increase their production rates.

Versatility

Circular slitter blades can be used to cut a wide range of metals, including steel, aluminum, copper, and brass. They can also be customized to cut different thicknesses and widths of metal coils.

Reduced downtime

High-quality circular slitter blades are durable and require less frequent sharpening or replacement, reducing downtime and maintenance costs.

Improved safety

Circular slitter blades are designed with safety in mind, with features such as blade guards and automatic shutoff systems that protect operators from accidents.

Cost-effective

Circular slitter blades are a cost-effective solution for metal slitting operations, as they offer high precision cutting at a relatively low cost compared to other cutting methods.

Round Packaging Machinery Blade

Round packaging machinery blade is an essential tool used in the packaging industry. It is responsible for ensuring that products are properly packaged and prepared for shipping. This blade is designed to be durable and efficient, allowing businesses to cut down on their production time and increase their output.

Round paper cutting blade is a useful tool that can make precise cuts on paper with ease. It is a perfect tool for those who work with paper on a regular basis or those who enjoy paper crafting as a hobby.

Rubber cutting blades are an essential tool for many industries that work with rubber materials. These blades are designed to cut through rubber with ease and precision, allowing for accurate cuts that ensure the material is properly sized for its intended use. With the right rubber cutting blade, workers can significantly improve their efficiency and accuracy in their work.

Why Choose Us

Factory

The company is a professional industrial cutting tool production and processing enterprise. The company team has 15 years of industry experience. Through years of continuous accumulation and exploration, it has successfully completed technological transformation.

High-quality service

We insist on returning the support and love of our customers and friends from all parties with stable, reliable, economical, durable and high-quality products.

Customized service

Our team of experts will work closely with you to understand your needs and provide tailor-made solutions to meet your expectations.

Competitive price

We are confident in the quality of our products and are willing to provide you with long-term technical service support.

Types of Circular Slitter Blades

Solid carbide slitter knives

Solid carbide slitter knives are made from a single piece of carbide material, which makes them highly durable and resistant to wear and tear. They are ideal for cutting abrasive materials such as stainless steel or hardened metals.

High-speed steel slitter knives

High-speed steel slitter knives are made from a special type of steel that can withstand high temperatures and speeds without losing its sharpness. They are versatile and can be used for cutting a wide range of metals, including aluminum, copper, and brass.

Ceramic slitter knives

Ceramic slitter knives are made from a high-tech ceramic material that is extremely hard and wear-resistant. They are ideal for cutting materials that require high precision and can withstand extreme temperatures.

Diamond-coated slitter knives

Diamond-coated slitter knives are coated with a layer of industrial-grade diamonds, which makes them highly durable and resistant to wear and tear. They are ideal for cutting hard and abrasive materials such as composites, fiberglass, and carbon fiber.

Tungsten carbide slitter knives

Tungsten carbide slitter knives are made from a combination of tungsten and carbon, which makes them highly resistant to wear and tear. They are ideal for cutting materials that require high precision, such as thin metals or paper.

Differences between Rotary Slitter Knives and Circular Slitter Blades

Design differences

Rotary slitter knives and circular slitter blades differ significantly in their design. Rotary slitter knives typically consist of a fixed blade mounted on a rotating shaft. This design allows the blade to rotate in a circular motion, slicing through materials as they pass through the cutting area. The blade itself is often rectangular or trapezoidal in shape, with a sharp cutting edge along one side.

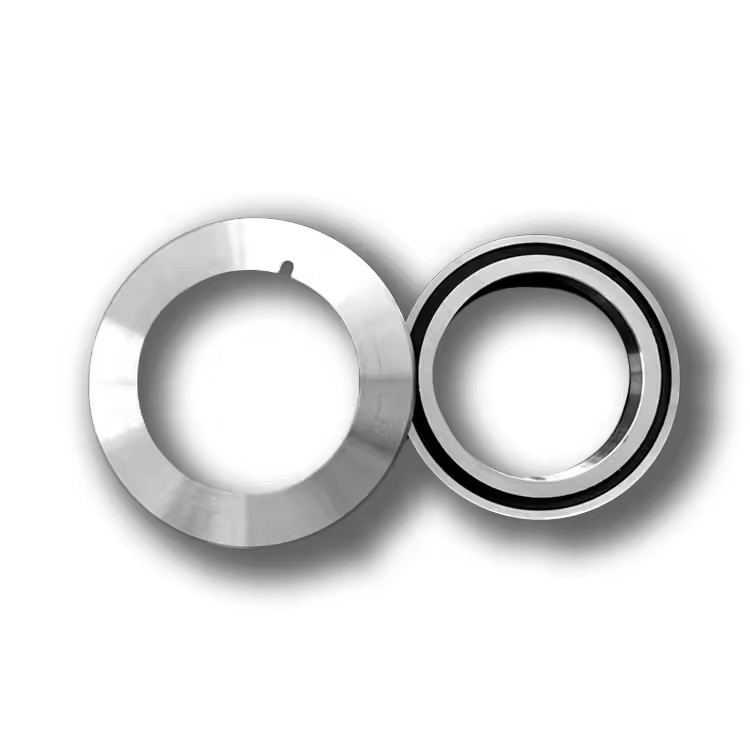

On the other hand, circular slitter blades have a circular shape with a sharp cutting edge around the perimeter. They are mounted on a machine or assembly line and rotate at high speeds, slicing through materials as they come into contact with the blade. The circular design allows for a more uniform cutting action and a larger cutting surface area, making them suitable for high-volume production.

Cutting efficiency differences

When it comes to cutting efficiency, both rotary slitter knives and circular slitter blades have their advantages. Rotary slitter knives excel in precision cutting, as their fixed blade design allows for more controlled and accurate slicing. This is particularly beneficial in applications where precise cutting dimensions are crucial, such as in the textile or packaging industries.

However, circular slitter blades often offer higher cutting speeds due to their continuous rotation. The circular motion allows for a faster and more consistent cutting action, which can significantly increase production throughput. This makes circular slitter blades a better choice for high-volume applications where speed and efficiency are paramount.

Durability differences

Durability is another key factor that distinguishes rotary slitter knives and circular slitter blades. Rotary slitter knives, with their fixed blade design, may be more prone to wear and tear, especially in applications that involve cutting abrasive or tough materials. The constant friction and impact can gradually dull the blade's edge, reducing its cutting performance over time.

On the contrary, circular slitter blades are often made from harder and more wear-resistant materials, such as high-carbon steel or carbide. This increased durability allows them to maintain their sharpness and cutting performance for longer periods, even with continuous use. Additionally, the circular design distributes the cutting force more evenly across the blade's perimeter, reducing the likelihood of premature wear or damage.

Cost differences

Cost considerations also play a role in choosing between rotary slitter knives and circular slitter blades. Rotary slitter knives may have a lower initial purchase cost compared to circular slitter blades, especially for smaller or simpler cutting applications. However, the long-term costs of ownership may be higher due to the need for frequent blade replacements and maintenance.

Circular slitter blades, on the other hand, may have a higher initial investment but offer longer-term cost savings. Their durability and longer lifespan reduce the frequency of blade replacements, minimizing downtime and maintenance costs. In high-volume production environments, the increased cutting efficiency and reduced downtime can offset the initial cost, making circular slitter blades a more cost-effective choice over the long run.

Application of Circular Slitter Blades

Cutting paper

Round slitter blades are regularly utilized in paper mills or printing centers to cut massive rolls of paper into smaller widths or lengths.

Converting films and foils

In manufacturing industries that produce films, foils, or laminates, round slitter blades are used to precisely cut those materials to unique dimensions.

Textile industry

Circular slitter blades are utilized inside the textile enterprise for reducing fabrics, textiles, or non-woven substances into preferred shapes or sizes.

Packaging

Circular slitter blades are important within the packaging enterprise for slicing materials like cardboard, corrugated board, or plastic sheets to create packaging substances of various shapes and sizes.

Metalworking

In metalworking operations, round slitter blades are hired to reduce metal sheets or coils into strips or blanks for similarly processing or fabrication.

Rubber and plastic processing

Circular slitter blades are utilized in industries that paintings with rubber or plastic substances, together with within the production of gaskets, seals, or plastic movies.

Food processing

Rotary slitter blades are utilized inside the meals industry for reducing materials like plastic films or foils used in food packaging, or for reducing sure food merchandise.

Material of Circular Slitter Blades

High-speed steel (HSS)

High-speed steel (HSS) stands as one of the most prevalent choices for industrial circular slitter blades. Renowned for its exceptional wear resistance, hardness, and ability to maintain sharp cutting edges even under high temperatures, HSS blades offer versatility across a broad spectrum of materials. This includes paper, plastics, and metals. Notably, HSS blades exhibit robust toughness, enabling them to withstand the demanding rigors of high-speed cutting processes without compromising on performance.

Tungsten carbide (WC)

Tungsten carbide emerges as a material of choice for applications demanding exceptional hardness and wear resistance. Circular slitter blades crafted from tungsten carbide demonstrate remarkable durability, retaining sharp edges for extended durations. This results in prolonged blade life and reduced downtime for sharpening or replacement. Particularly suited for cutting abrasive materials like fiberglass, carbon fiber, and composites, tungsten carbide blades excel in challenging cutting environments.

Ceramics

Ceramic circular slitter blades are gaining prominence in industries requiring superior wear resistance and cutting precision. These blades are fashioned from advanced ceramic materials such as zirconia or alumina, renowned for their exceptional hardness, chemical inertness, and resistance to wear and heat. Ceramic blades find application in high-precision cutting tasks, notably in electronics manufacturing and semiconductor production, where clean, precise cuts are imperative for optimal performance.

Diamond coatings

Some industrial circular slitter blades incorporate diamond coatings to elevate their cutting prowess and longevity. Diamond coatings confer extreme hardness and abrasion resistance to the blades, enabling them to effortlessly cut through tough materials while retaining sharpness over prolonged use. Widely used in cutting applications involving highly abrasive materials like glass, ceramics, and hard metals, diamond-coated blades exemplify durability and reliability in demanding cutting environments.

Carbide-tipped

Circular slitter blades featuring carbide tips combine the toughness of steel with the hardness of carbide to deliver superior cutting performance. These blades boast a steel body with carbide inserts or tips brazed onto the cutting edges. Carbide-tipped blades offer exceptional wear resistance and cutting precision, making them well-suited for demanding applications such as cutting corrugated cardboard, rubber, and textiles. Their versatility makes them a preferred choice across various industries.

How to Improve the Service Life of Circular Slitting Blades

Surface heat treatment

Through proper surface heat treatment technology, the development and transformation of the organization management structure of chinese metals can be made, the surface hardness of cutter blade can be improved and the wear resistance can be increased. The circular blade forms a circular shape outside, and generally, it is used in mechanical equipment, mainly cutting, trimming and other processing functions. The circular blade usually has a middle hole, which is designed to fix it on the mechanical equipment, thus achieving the cutting function. There are also many round blades with teeth (flat teeth, sharp teeth, irregular teeth), and the cutting edge has three types: Double-sided, single-sided and non-cutting edge.

Layer technology

Layer technology is a chemical heat treatment method to change the chemical composition of cutter blade surface and improve the wear resistance and corrosion resistance of cutter blade.

Plating technology

Electroplating is a traditional chinese method of protection research. The adaptability of electroplating is very strong, and it is not affected by the size and batch of workpiece. It can be electroplated on iron base, non-iron base, powder metallurgy parts, plastics and graphite.

Thermal spraying technology

Thermal spraying technology is a method of heating metal, alloy, cermet, oxide, carbide and other spraying materials to melting or semi melting state by using gas, liquid fuel or arc and plasma arc as heat source. The solid surface layer is atomized, sprayed and deposited by high-speed airflow on the surface of the workpiece.

Coating technology

Coating treatment technology is a kind of material and surface chemical modification research technology developed in china in the early 1970s. It can be applied a thin layer of refractory element gold (or non-metallic) compound with high wear resistance on the cutter blade structure base by our certain method to improve the durability, corrosion resistance and high-temperature oxidation resistance of the cutter blade.

How to Choose a Circular Slitter Blades

Material compatibility

First and foremost, compatibility between the circular slitter blades and the material being cut is imperative. Different materials exhibit varying degrees of hardness, abrasiveness, and elasticity, necessitating tailored blade designs and materials to ensure optimal performance.

For instance, while high-speed steel (hss) blades excel in cutting soft materials like paper and textiles, tungsten carbide blades are better suited for abrasive materials such as rubber and composites.

Blade geometry

The geometry of the circular slitter blades plays a pivotal role in determining the quality and precision of the cut. Factors such as blade diameter, thickness, and edge configuration must be carefully considered to accommodate the specific requirements of the material.

For thin, delicate materials like films and foils, blades with fine serrations or micro-serrated edges provide enhanced control and minimize the risk of tearing or distortion during cutting. Conversely, thicker materials may benefit from blades with larger diameters and robust edge profiles to ensure clean, consistent cuts without compromising efficiency.

Coating and surface treatment

The application of specialized coatings and surface treatments can significantly enhance the performance and longevity of circular slitter blades, particularly when cutting challenging materials or operating under harsh conditions. Titanium nitride (tin), titanium carbonitride (ticn), and diamond-like carbon (dlc) coatings offer superior wear resistance and reduce friction, thereby extending blade life and minimizing the need for frequent sharpening or replacement.

Additionally, surface treatments such as cryogenic hardening or nitriding can further enhance the hardness and durability of the blades, ensuring sustained performance over prolonged use.

Cutting speed and feed rate

Optimizing the cutting speed and feed rate is essential to achieve efficient material processing while minimizing wear and tear on the circular slitter blades. The ideal cutting parameters vary depending on factors such as material type, thickness, and machine configuration.

For softer materials, higher cutting speeds and feed rates may be feasible, whereas harder or heat-sensitive materials may require slower, more controlled cutting to prevent overheating and premature blade dulling. Experimentation and adjustment of cutting parameters are often necessary to strike the right balance between productivity and blade longevity.

Machine compatibility and alignment

In addition to selecting the appropriate circular slitter blades, ensuring proper machine compatibility and alignment is crucial for achieving optimal cutting performance. Blades must be installed securely and aligned accurately with respect to the material feed direction to prevent deflection, vibration, or uneven cutting.

Regular maintenance and inspection of the cutting equipment, including blade holders, spindles, and guide mechanisms, are essential to detect and rectify any issues that may compromise cutting quality and blade integrity.

Our Factory

Ganzhou Big Brother Cutting Tools Co., Ltd. is a professional manufacturer and processor of industrial cutting tools. The company team has 15 years of industry experience and has successfully completed technological transformation through years of continuous accumulation and exploration.Also skilled in researching and producing non-standard cutting tools, molds, etc The main products include: packaging machine knives, non-standard blades, industrial knives, food machine knives, woodworking planers, alloy blades, precision knife molds, shredder knives, agricultural machinery knives, and various mechanical cutting tools for mass production and non-standard customization.

FAQ

Q: What are slitter blades used for?

Q: What is a circle knife used for?

Q: What material is used for slitting blades?

Q: What angle should a slitter knife be?

Q: What is the purpose of a slitter?

Q: What is the function of a slitter?

Q: Why do Japanese knives have round handles?

Q: What is a round bladed knife used for?

Q: What are the advantages of round knife?

Q: What is slitting in steel?

Q: What is a slitting saw used for?

Q: What is slitting cut?

Q: What is a slitter knife?