Description

Carbide end mills can significantly improve your efficiency in machining products. A chemical coating is applied to carbide end mills to reduce friction when cutting materials, further enhancing overall performance.

Product Specifications

We offer many different specifications and can customize to your equipment. Below are some common specifications:

| |||

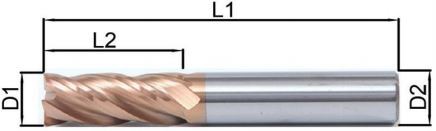

| DC (D1) | Flute Length (L2) | Dia.of Shank (D2) | Overall Length (L1) |

| 1.0 | 3 | 4 | 50 |

| 1.5 | 4 | 4 | 50 |

| 2.0 | 5 | 4 | 50 |

| 2.5 | 6 | 4 | 50 |

| 3.0 | 8 | 4 | 50 |

| 4.0 | 10 | 4 | 50 |

| 5.0 | 13 | 6 | 50 |

| 6.0 | 15 | 6 | 50 |

| 7.0 | 18 | 8 | 60 |

| 8.0 | 20 | 8 | 60 |

| 9.0 | 22 | 10 | 75 |

| 10.0 | 25 | 10 | 75 |

| 11.0 | 25 | 12 | 75 |

| 12.0 | 30 | 12 | 75 |

| 14.0 | 35 | 14 | 100 |

| 16.0 | 45 | 16 | 100 |

| 18.0 | 45 | 18 | 100 |

| 20.0 | 45 | 20 | 100 |

| Long shank | |||

| DC (D1) | Flute Length (L2) | Dia.of Shank (D2) | Overall Length (L1) |

| 3 | 12 | 4 | 75 |

| 4 | 14 | 4 | 75 |

| 5 | 18 | 6 | 75 |

| 6 | 21 | 6 | 75 |

| 3 | 12 | 4 | 100 |

| 4 | 16 | 4 | 100 |

| 5 | 20 | 6 | 100 |

| 6 | 24 | 6 | 100 |

| 8 | 32 | 8 | 100 |

| 10 | 40 | 10 | 100 |

| 12 | 45 | 12 | 100 |

| 6 | 45 | 6 | 150 |

| 8 | 50 | 8 | 150 |

| 10 | 55 | 10 | 150 |

| 12 | 60 | 12 | 150 |

| 16 | 70 | 16 | 150 |

| 20 | 75 | 20 | 150 |

Carbide End Mill Components

Structure: Carbide end mills are cylindrical in shape with a helical cutting edge at the tip.

Function: Primarily used for machining various metals, alloys, or plastics.

Key Components

1. Shank: Requires use with a milling machine. The entire tool is screwed onto the milling machine spindle.

2. Cutting Edge: The main component responsible for cutting the material.

3. Groove: Generally helical or straight. Different types of grooves produce different shapes; choose according to the actual operation.

4. Core Diameter/Web Thickness: Requires selection based on the thickness of the mold. Different molds have varying cutting strengths and rigidities.

5. Number of flutes: The number of flutes varies depending on the actual mold, such as 2, 3, 4, or more. The number of flutes affects cutting space and efficiency, so we can choose based on the specific number.

Core Product Features

Core Material: carbide end mill bits

Composition: Carbide end mills are made by combining tungsten carbide and cobalt, then forging under high temperature and pressure. This combination gives them extremely high durability and allows for long-term use.

Ultra-High Hardness: Our carbide end mills have a hardness close to diamond, harder than ordinary high-speed steel. Therefore, they can be used to machine difficult-to-machine materials such as hardened steel.

Wear Resistance: Using our carbide end mills can significantly reduce your tool change frequency, helping you save considerable costs.

Sustainable High Temperatures: Even at extremely high temperatures (above 800 degrees Celsius), carbide end mills maintain their hardness and cutting performance, so you can confidently use them continuously at high temperatures. High Strength: Carbide end mills possess exceptional compressive strength, easily handling even materials with high hardness.

Introduction to Carbide End Mill Coating Types:

To enhance the performance of carbide end mills, one or more protective coatings are applied to their surface to improve wear resistance and oxidation resistance. Common coating types include:

1. TiN (Titanium Nitride): A general-purpose coating, gold in color.

2. TiCN (Titanium Carbonitride): Adds carbon atoms to TiN, resulting in significantly higher hardness. Bluish-gray in color.

3. TiAlN (Titanium Aluminum Nitride): TiAlN coatings are commonly used to increase the machining capability of carbide end mills at high temperatures. This coating is purplish-gray or black and improves oxidation resistance and machining efficiency at high temperatures.

4. AlTiN (TiAlTiN): Very similar to TiAlN in both appearance and properties, though performance varies depending on the aluminum-to-titanium ratio.

5. Diamond-like carbon (DLC): Also a black coating. Its extremely low coefficient of friction makes it ideal for processing non-ferrous metals like aluminum and graphite.