Description

Product introduction

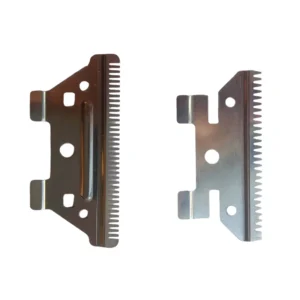

Sharp sealing machine blades

The serrated blade features multiple sharp teeth edges, which are ideal for cutting. The main body of the blade is made of high-quality materials such as stainless steel, and has a coating on the surface that is resistant to wear and corrosion. There are rectangular protrusions at both ends of the blade, which are used for mounting onto the carton sealing machine.

The working principle of the carton sealing machine blade involves the blade working in conjunction with the machine's transmission system. It operates at high speeds during the automated packaging process to cut the tape and quickly seal the carton, thus enhancing production efficiency and quality.

Product features

High Hardness

Our carton sealer blade is made of high-quality high-carbon steel material that has been heat-treated, and the hardness can reach HRC 58-62. This is about 20% higher than the hardness of ordinary carbon steel blades (usually HRC 45-50). Therefore, our blade can continuously cut 5,000 standard 3-layer corrugated boxes and remain sharp, while ordinary blades need to be replaced after cutting 3,000.

Smooth Cutting

We use precision CNC grinding technology to control the blade edge angle within the range of 15°±0.5°, and the edge line width is only 0.01mm. Therefore, our blade can achieve clear cuts without burrs and tears on cartons of various thicknesses (1mm-10mm), and the cut flatness reaches ±0.1mm. In contrast, the cut flatness of traditional blades is usually around ±0.3mm.

Corrosion Resistance

Our blades are treated with Cr-N (chrome nitrogen) composite coating, which can effectively resist corrosion in humid, acidic and alkaline environments. After 500 hours of salt spray test according to ASTM B117 standard, there is still no obvious rust on the surface of our blades, while ordinary stainless steel blades will show obvious rust after 200 hours.

Safety

Our blades are electrolytic passivation treated. While ensuring the sharpness of the cutting edge, the sharpness of the non-cutting part is reduced by 50%, and the contact pressure is increased from the original 0.5N to 1.5N before scratching the skin, greatly reducing the risk of scratches on the operator.

Customizable

Product customization steps

![]()

Determine the requirements

Model, thickness, and specifications of the sealing machine

![]()

Product design

Use CAD software to design the shape, size, and tooth profile of the blades.

![]()

Material selection

Choose high-hardness materials such as high-speed steel and tungsten carbide.

![]()

Precision processing

Utilize advanced processing equipment and heat treatment.

![]()

Quality testing

Conduct strict hardness and wear resistance tests

![]()

Trial operation

Install the blades onto the sealing machine to check the cutting effect.

![]()

Packaging and delivery

Strongly package the qualified blades for delivery

![]()

After-sales service

Provide technical support and maintenance services

FAQ

Q: Are you manufacture or trading company?

Q: Can you customize carbdie tools?

Q: Can I get samples before my order?

Q: What kind of payment torment we can use?

Q: What is the delivery time if I place my order?

Q: Can I Put My Logo On The Product?