Description

Product introduction

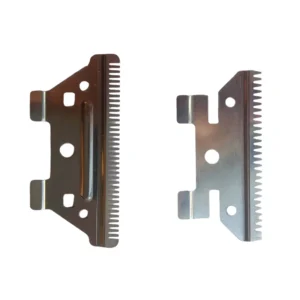

The Charter machine blade is a cutting tool. It is used to cut large pieces of material into the required size or shape, and is widely used in the processing of metal, plastic, paper, wood and other materials.

Product features

High Hardness

The Charter machine blade uses M4 steel material. After precision heat treatment, the tool hardness can reach HRC 64-66, which is 3-5 HRC points higher than traditional high-speed steel tools. Such high hardness makes the Charter knife have a blade wear of no more than 0.01mm after continuously cutting 100,000 meters of paper, while the blade wear of ordinary carbon steel knives is usually 0.05mm.

High Precision

The blade angle of the Charter machine blade is precisely controlled at 18°±0.5°, and the blade radius can reach less than 1μm. This precision enables its cutting tolerance to be controlled within ±0.005mm, which is 4 times higher than the industry standard ±0.02mm.

High Toughness

Through the unique triple tempering process, Charter machine blades maintain high hardness while achieving an impact toughness of 60 J/cm², which is 30% higher than standard M2 high-speed steel. This means that under 24-hour continuous operation, the probability of a Charter machine knife breaking is less than 0.01%, while the breakage rate of ordinary knives may be as high as 1-2%.

Good Thermal Stability

The special alloy composition (containing 4.5% Mo, 6% W, 5% Cr) makes our blades have high thermal stability. At an operating temperature of 250℃ for 8 hours, the hardness and sharpness of the blade will not decay by more than 5%. In contrast, the hardness of common blades on the market will drop by 15-20% after working at 180℃ for 4 hours.