Description

A Crusher Blade is a tool or component used in crushers and shredders to cut or shred materials into smaller pieces or particles. These blades are typically made from high-quality steel or alloy materials to withstand the impact and abrasion of crushing various materials such as plastic, wood, metal, and more. Crusher blades come in different shapes, sizes, and configurations depending on the specific application and material being processed. They play a crucial role in the efficiency and effectiveness of the crushing or shredding process.

Advantages of Crusher Blade

Strong wear resistance

The shredder blade is made of high-strength alloy steel with excellent wear resistance. Whether processing scrap metal or plastic, the shredder blade remains sharp for a long time and is not easy to wear, reducing the frequency of shredder blade replacement

High reliability

The shredder blade is precisely processed, with a stable structure and a firm connection, so that the blade has excellent reliability under high load, can operate stably for a long time, and reduce failures and downtime.

Versatile application

The shredder blade can adapt to the processing needs of a variety of materials. Whether processing scrap metal, plastic, textiles or wood, the blade can effectively shred and crush to meet the needs of different industries.

Safety protection measures

The blade is installed in the sealed chamber of the double-shaft shredder, which effectively reduces the risk of operators. The machine is equipped with safety protection devices such as safety switches and protective covers to ensure safety during operation and protect the personal safety of operators.

Effortlessly mince, chop, grind and blend a variety of ingredients for easy meal preparation or final touches

Perfect for garlic, onion, zest, spices, herbs, cheese, bacon crumbles, nut chopping, chocolate, dressings, sauces and spreads

Woodworking forming blades are essential tools for any woodworking professional or hobbyist. These blades are used for shaping and forming wood, creating intricate designs, and achieving a smooth finished product.

Woodworking Steel Planer Blade

One major advantage of Woodworking steel planer blade is their durability. This tool is made of high-quality steel and can withstand a large amount of use with a long service life. This means you don't have to worry about replacing the blades after each project, nor do you have to worry about purchasing new blades due to blade wear. With proper maintenance and upkeep, steel planer blades can continue to provide excellent results in the coming years.

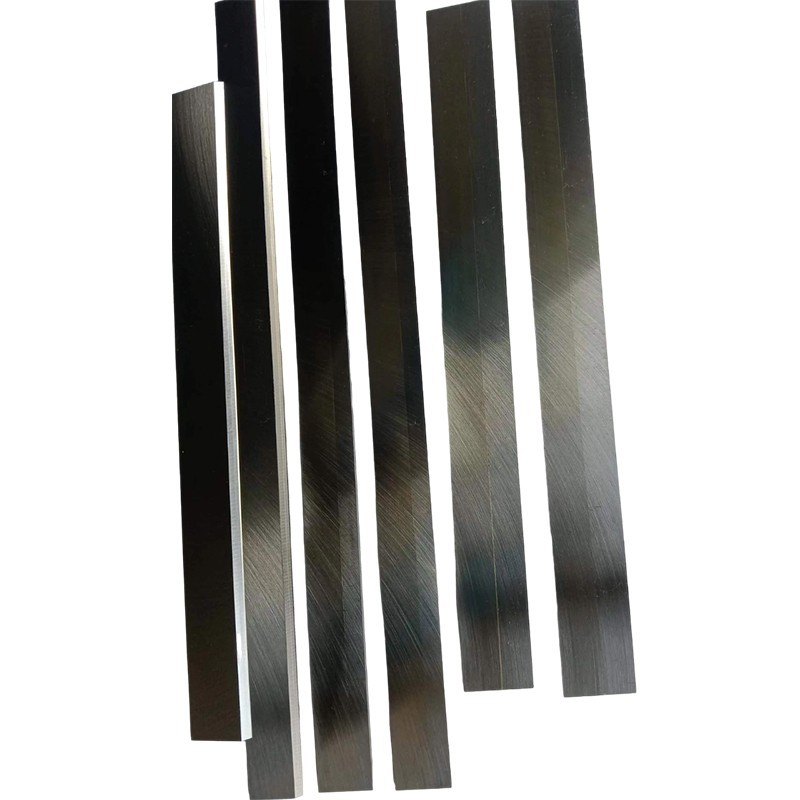

Crusher blade using flat design, divided into the moving knife and the fixed knife, usually a pair of grinder blades are 5 pieces, consists of 3 pieces of grinding moving knife and 2 pieces of fixed knife, through moving knife's high speed rotating and stationary knife's shearing to crush plastic materials, can adjust grinding knife to control the size of crush granule.

PE film slitting blade is a crucial component in the process of slitting plastic films. It plays a significant role in ensuring that the cut edges of the film are precise, smooth and without any burrs. With the rapid advancement of technology, there has been an increased demand for high-quality slitting blades that can meet the growing needs of various industries.

Semiconductor punching blades are an essential tool for the manufacturing of semiconductor products. These blades are specifically designed to cut through the hard and delicate materials used in the fabrication process.

Laminating machine blade machines are essential for keeping important documents and papers safe and secure from any damages. They use a blade to cut the laminating film to the appropriate size and shape. The blade is a crucial component in a laminating machine as it ensures that the lamination process is precise and effective.

Easy-tear cutting blade Widely used in mechanical manufacturing and processing industries and fields such as papermaking, packaging, printing, film, new materials, rubber and plastic, food, chemical industry, light textile, metallurgy, landscaping and woodworking, electronics and appliances, construction engineering, automobiles and ships, aerospace, etc.

One of the main benefits of using harvester blades is their durability. These blades are made from high-quality materials that are designed to withstand the rigors of daily use. They are also easy to maintain, ensuring that they remain in top condition for many years to come.

Why Choose Us

Factory

The company is a professional industrial cutting tool production and processing enterprise. The company team has 15 years of industry experience. Through years of continuous accumulation and exploration, it has successfully completed technological transformation.

High-quality service

We insist on returning the support and love of our customers and friends from all parties with stable, reliable, economical, durable and high-quality products.

Customized service

Our team of experts will work closely with you to understand your needs and provide tailor-made solutions to meet your expectations.

Competitive price

We are confident in the quality of our products and are willing to provide you with long-term technical service support.

Types of Crusher Blade

Flat blade

Flat blade is a classic crusher blade, usually used to process fragile and regular shaped raw materials, such as plastic, rubber, wood, etc. The blade has a simple structure, is easy to process and repair, and is suitable for small crushers and low-power crushers.

Claw blade

Claw blade is a common crusher blade, usually used to process hard or sticky raw materials, such as rubber tires, plastic pipes, aged rubber products, etc. The blade has a special structure and has strong tearing and extrusion capabilities, which can effectively crush raw materials.

Double shaft blade

The double shaft blade is a high-performance blade suitable for processing large and hard materials, such as scrap cars, ships, construction waste, etc. The blade has a complex structure, consisting of blades mounted in opposite directions on two shafts, which can achieve efficient crushing and separation.

Shear blade

Shear blade is a special blade suitable for processing roll or thin sheet raw materials, such as scrap steel plates, iron sheets, etc. The blade has a unique structure, consisting of multiple staggered edges, which can quickly and evenly shear raw materials.

Serrated blade

Serrated blade is a blade specially designed for processing wood and wood materials, which can achieve efficient crushing and cutting. The blade structure is similar to saw teeth, which can quickly split wood into the desired shape and size.

Application of Crusher Blade

Crusher blades are an important mechanical component that is widely used in multiple industries and scenarios. The following are some of its main application scenarios: Mining field In the mining industry, crusher blades are mainly used for the preliminary crushing and processing of ore for subsequent beneficiation and processing. Especially in hard rock mines such as gold and copper mines, they are widely used due to their efficient cutting ability. Construction waste treatment the process of recycling and reuse of construction waste, crusher blades can effectively break up discarded concrete blocks and other materials into suitable particle sizes for reuse. This can not only reduce environmental pollution problems, but also save resource costs. Forestry waste treatment For large amounts of forest waste such as wood waste or dead wood and branches, crusher blades can perform effective cutting and crushing operations to convert them into biomass fuels or other renewable products such as wood chip boards. Other uses in industrial manufacturing In addition, there are many other occasions for using crushers in the industrial field, such as recycled plastic granulation in plastic material production, etc. In these production processes, crusher blades are one of the indispensable accessories. Their sharp cutting performance can improve production efficiency and reduce costs. In short, crusher tools can find their place in almost all industrial production processes.

The Reasons for the Damage of the Crusher Blade May Be as Follows

Blade quality

If the blade is used improperly, it is easy to cause damage or wear of the blade during use.

Blade installation problem

If the blade is not installed correctly, the blade will be unevenly stressed during use, causing damage to the blade.

Plastic material problem

If the crushed plastic material contains impurities or hard objects, it will cause greater wear or impact on the blade, thereby damaging the blade.

Improper operation

If the operator uses it improperly, overuses the blade or uses the blade improperly, it will also cause damage to the blade.

Improper maintenance

If the blade is used for a long time without maintenance or replacement, it will also cause severe wear and damage to the blade.

Process of Crusher Blade

As we all know, the processing technology of mechanical blades is complicated. Compared with other blades, the processing technology of crusher blades is relatively simple. Of course, the relatively simple processing technology will not lead to the quality difference between blades and other types of blades. However, compared with the dozens of processes of other mechanical blades, the process of crusher blades is about nine, which simplifies many unnecessary processes, and the reduction of these processes is not at the expense of the quality of the blades.

Simplifying the processing process does not mean that this is arbitrary production, and it must also comply with the standard process of the industry. While simplifying, it is also necessary to ensure that the hardness and size of the blade meet the use requirements. Never equate the simplified production of crusher blades with low-quality production. There is no inevitable relationship between the two. If the hardness does not meet the requirements, the crusher blade will not be durable, and if the size does not meet the standard, the blade cannot be installed on the machine normally. What is the use of a knife that cannot be installed. Crusher blades are mainly simpler and more precise than circular blades, and there are bending machine molds. In fact, processing is still not that easy.

As for the processing steps of the blades, starting from material selection, furnace forging with high-quality materials, to fine grinding, each process is strictly controlled. Improper operation of any link will damage the blade. Once discovered, the processed crusher blade will be treated as scrap iron and continued to be processed with new materials to ensure that simple processes can also produce high-quality tools.

How to Choose a Crusher Blade

Different types of blades have different hardness and toughness, so it is necessary to select appropriate blade materials and shapes according to different blade types. For example, for hard blades, you can choose claw knives; for soft blades, you can choose blade knives.

Different processing conditions have different requirements for blades. For example, for production lines with high output requirements, you can choose blades with high cutting efficiency and wear resistance; for occasions with high processing accuracy requirements, you can choose blades with high precision.

Blade material is an important factor affecting blade performance and service life. Common blade materials include tool steel, alloy steel, cemented carbide, ceramic, etc. Blades of different materials have different hardness, wear resistance, corrosion resistance and other characteristics, and need to be selected according to actual needs.

Blades of different brands and qualities have different service lives. When selecting blades, it is necessary to consider the service life and replacement cycle of the blades so that worn blades can be replaced in time to ensure the stable operation of the production line.

When selecting crusher blades, it is necessary to consider factors such as price and processing cost. On the premise of ensuring product quality and performance, choose affordable and cost-effective blades.

Crusher blades are also composed of various components. Before installation, all equipment parts should be checked, and check the main steel structure, bearings, bolts and other conditions. At the same time, should record the surface condition of the parts whether anti-corrosion, for future inspection.

The design of crusher blade should be reasonable, generally using alloy steel blade, so that the product granulates evenly, knife seat for heat shrinkage treatment. Finally, the mill blade has passed the strict balance test, the appearance design is also beautiful and generous. The structure of crusher blade is between claw knife and flat knife, suitable for crushing plastic products such as ordinary sheet, pipe, profile, plate, packing material and so on.

Secondly, the universal crusher blade uses sealed bearing, so that the bearing can keep good rotation for a long time. The major repair of crusher blade equipment means that the equipment is worn or damaged seriously, and the mechanical properties are obviously reduced. At this time is a major overhaul, such as mechanical dynamic performance decreased significantly, increased fuel consumption, poor operation, abnormal sound, or equipment can no longer play a normal production performance. At this time should be in accordance with the provisions of maintenance, scheduling work.

Safety Precautions When Using the Crusher Blade

- Carefully protect the alloy tips to prevent damage.

- Regularly check the radial runout and swing of the main shaft to ensure proper blade alignment.

- Clean the main shaft and flange before installation; the flange surface should be flat, clean, and perpendicular to the shaft.

- Use the largest possible flange to stabilize blade operation, ideally one-third (or half for thin blades) the diameter of the blade for optimal cutting.

- After installation, allow the blades to rotate freely for 30 seconds to ensure everything functions normally before beginning operations.

- Ensure the flange nuts are tightened appropriately to prevent the blade from slipping or causing internal damage during operation.

- Operators must wear protective gear (safety glasses, dust masks, helmets, and gloves) and ensure the protective guard of the saw machine is intact.

Want to Know How to Choose the Material of the Crusher Blade

Crushing type

If the crushing is of ordinary hardness, such as polyethylene (PE), polypropylene (PP), etc., tool steel or alloy steel blades may be sufficient. For projects with higher hardness, such as polycarbonate (PC), nylon (PA), etc., you may need to choose carbide or high-chromium cast iron blades to ensure sufficient wear resistance and cutting ability.

Crushing volume and working intensity

Crushers with high output and long-term continuous operation require more wear-resistant and higher-strength materials, such as carbide. In the case of small crushing volume and low working intensity, tool steel or alloy steel materials can usually meet the needs and the cost is relatively low.

Budget

The cost of blades made of high-performance materials such as carbide is relatively high. If the budget is limited, alloy steel or tool steel materials can be considered first. But be aware that although the initial investment is low, frequent blade replacement may increase long-term costs.

Wear resistance requirements

When wear resistance requirements are very high, carbide or high-chromium cast iron is preferred. If wear resistance requirements are general, tool steel and alloy steel are also available.

Impact resistance requirements

If a large impact may be encountered during the crushing process, such as crushing plastics containing impurities or large plastic parts, materials with good impact resistance, such as alloy steel, should be selected.

Our Factory

Ganzhou Big Brother Cutting Tools Co., Ltd. is a professional manufacturer and processor of industrial cutting tools. The company team has 15 years of industry experience and has successfully completed technological transformation through years of continuous accumulation and exploration.Also skilled in researching and producing non-standard cutting tools, molds, etc The main products include: packaging machine knives, non-standard blades, industrial knives, food machine knives, woodworking planers, alloy blades, precision knife molds, shredder knives, agricultural machinery knives, and various mechanical cutting tools for mass production and non-standard customization.

FAQ

Q: What are crusher blades made of?

Q: What is a Crusher Blade used for?

Q: What materials are Crusher Blades typically made from?

Q: How do the design and shape of a Crusher Blade impact its performance?

Q: What are the different types of Crusher Blades available for various applications?

Q: How often should Crusher Blades be sharpened or replaced?

Q: What factors should be considered when selecting Crusher Blades for a specific material?

Q: How are Crusher Blades different from regular cutting blades?

Q: Can Crusher Blades be customized for specific shredding requirements?

Q: What maintenance practices can help prolong the lifespan of Crusher Blades?

Q: How do Crusher Blades contribute to the efficiency of the crushing process?

Q: Are there safety precautions to follow when handling Crusher Blades?

Q: What are the common sizes of Crusher Blades available in the market?

Q: How are Crusher Blades sharpened or maintained?

Q: Can Crusher Blades be used for recycling applications?

Q: What are the key components of a Crusher Blade?

Q: How do Crusher Blades impact the final product size in the crushing process?

Q: Are there specific maintenance schedules recommended for Crusher Blades?

Q: Can Crusher Blades be reconditioned or refurbished?

Q: How do Crusher Blades contribute to reducing material waste in industrial processes?