Description

Product Introduction

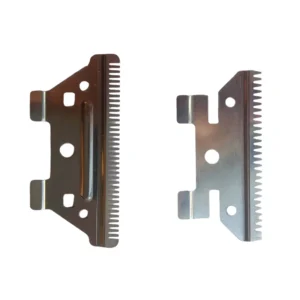

The metal blades at the top are evenly distributed with multiple circular holes, which can be used for fastening or coordinating with other mechanical components. The metal blades at the bottom have sharp edges that have been ground, allowing for precise cutting.

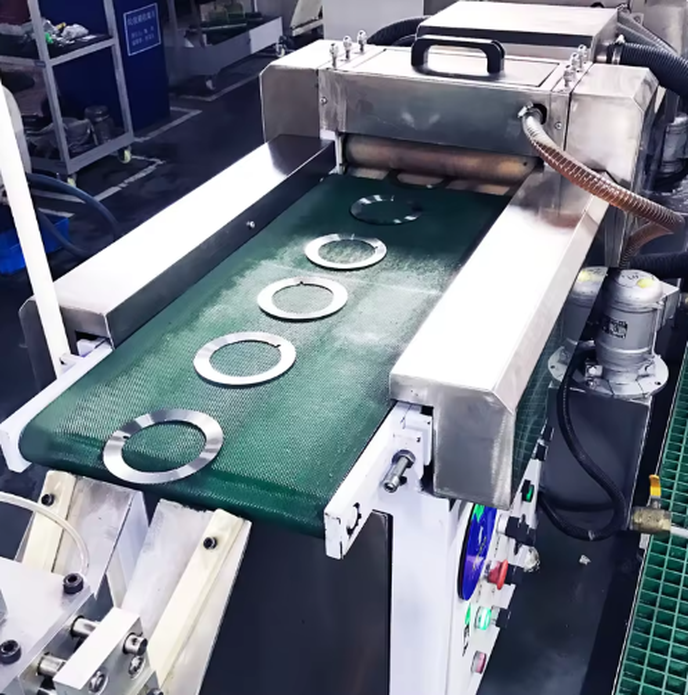

The Cutting Blade For Film Laminating is made of high-quality stainless steel, ensuring sharpness and resistance to corrosion, making them suitable for use in various industrial environments. The cutting blades used for film laminating are key components in laminating machines, often used for cutting and processing film materials. During operation, the blades rotate and move on the base plate, cutting the film material with their sharp cutting edges.

Product Features

High Strength

The Cutting Blade For Film Laminating for film laminating is made of 42CrMo alloy steel with a yield strength of 1250MPa and a tensile strength of 1450MPa. It can withstand an external force of 5000N without obvious bending or breaking. It allows the blade to remain stable under high load and high pressure working conditions, and is suitable for cutting operations that require high mechanical stress.

High-precision Cutting

The Cutting Blade For Film Laminating for film laminating uses electrospark machining (EDM) and electrolytic grinding processes, and the edge flatness error is controlled within ±0.001mm, the edge angle accuracy is ±1°, and the cutting size deviation is ±0.05mm.It is crucial for application scenarios that require fine processing, such as semiconductors, electronic component manufacturing, etc., which can ensure that the cut components meet strict size and shape requirements.

Waterproofness

The coating layer of the cutting blade for film laminating is polytetrafluoroethylene (PTFE). When water molecules come into contact with the coating layer, the contact angle is greater than 110°, and it is almost impossible to penetrate the coating layer and contact the blade substrate, effectively avoiding rust corrosion caused by water erosion, and ensuring that the cutting performance of the blade in a humid environment is not affected.

Application Scenarios

Packaging Industry

The packaging industry uses cutting and sealing equipment to cut and seal packaging materials such as films and paper to produce packaging boxes and bags, improving the quality and efficiency of packaging production.

Printing Industry

The printing industry uses cutting equipment to cut printing paper and laminated materials such as plastic films to produce labels and brochures, ensuring clean cutting edges and enhancing the appearance quality of printed materials.

Plastic Industry

The plastic industry utilizes the Cutting Blade For Film Laminating to cut plastic films and sheets to manufacture plastic packaging and containers, improving the accuracy and quality of plastic products.

FAQ

01. Q: Are you a trading company or a manufacturer?

02. Q: Can I place a sample order for the blade?

03. Q: What is your blade hardness?

04. Q: Does this blade require any special maintenance or care?

05. Q: What are the key points for the maintenance of cutting blade for film laminating?