Description

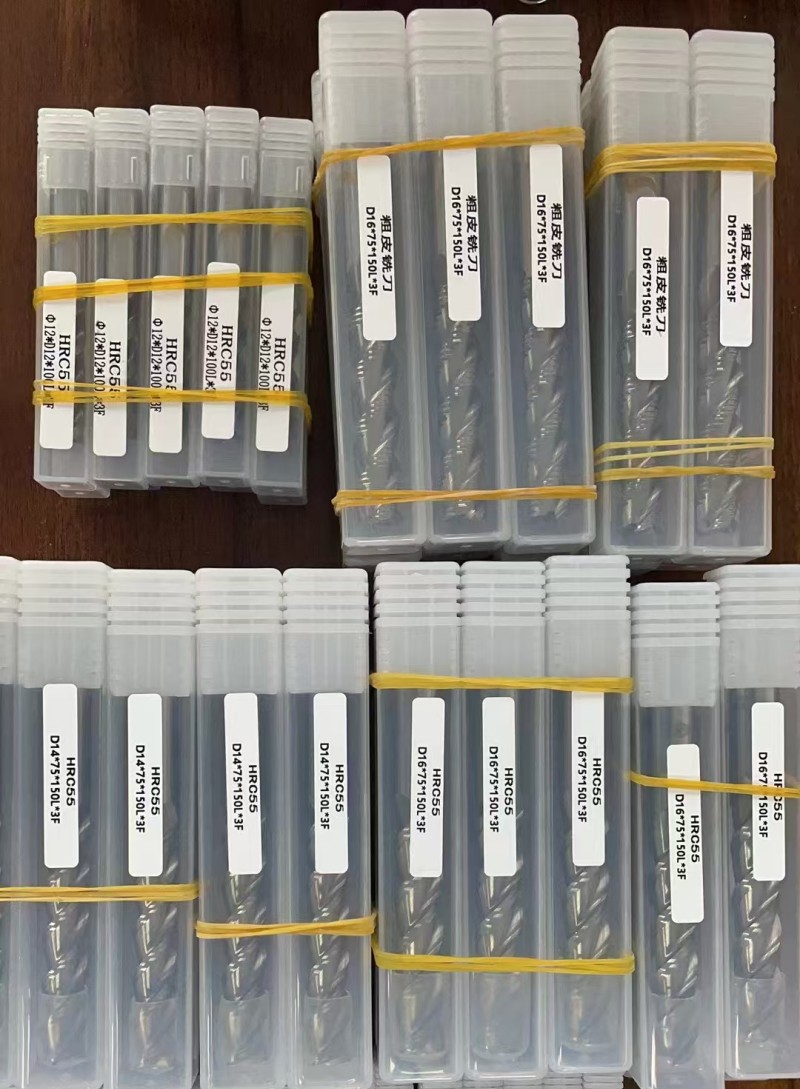

Products Description

Diamond coated carbide end mills are high-performance cutting tools widely used for machining extremely hard, highly wear-resistant, and abrasive materials.Let's break down their key components:

1.Carbide Substrate:

This is the tool's base material, formed by sintering tungsten carbide particles with cobalt (or other metals) as a binder under high temperature and pressure.Its function is to provide the structural strength, toughness and geometry required by the tool to support the diamond coating.

2.Diamond Coating:

An ultra-thin layer (typically a few micrometers thick) of synthetic polycrystalline diamond deposited onto the carbide substrate surface via Chemical Vapor Deposition (CVD).Its function is to act as a protective layer and a working layer, directly contact the processed material, provide ultra-high wear resistance, significantly extend tool life, and improve processing surface finish.

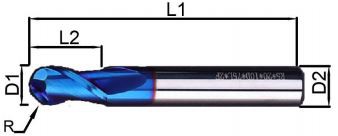

Products Specifications

Relevant chucks are also available.

Inches sizes or other shapes can be customized accordingly/custom design and build capabilities.

The Solid End Mills also can be made according to your own specifications.

| |||

| Radius of Cut (R) | Flute Length (L2) | Dia. of Shank (D2) | Overall Length (L2) |

| R0.5 | 2 | 4 | 50 |

| R0.75 | 3 | 4 | 50 |

| R1.0 | 4 | 4 | 50 |

| R1.25 | 5 | 4 | 50 |

| R1.5 | 6 | 3 | 50 |

| R1.5 | 6 | 4 | 50 |

| R1.75 | 7 | 4 | 50 |

| R2.0 | 8 | 4 | 50 |

| R2.5 | 10 | 5 | 50 |

| R2.5 | 10 | 6 | 50 |

| R3.0 | 12 | 6 | 50 |

| R4.0 | 16 | 8 | 60 |

| R5.0 | 20 | 10 | 75 |

| R6.0 | 24 | 12 | 75 |

| R7.0 | 28 | 14 | 100 |

| R8.0 | 32 | 16 | 100 |

| R9.0 | 36 | 18 | 100 |

| R10.0 | 40 | 20 | 100 |

Products Advantages

Superior Tool Life:

The most significant benefit. The Diamond coated carbide end mills drastically enhances resistance to abrasive wear, often extending tool life by 10x to 100x or more compared to uncoated carbide tools when machining highly abrasive materials.

01

Higher Cutting Speeds:

The low friction and high thermal conductivity allow for increased cutting speeds, boosting productivity.

02

Improved Surface Finish:

Low friction and a sharp cutting edge enable smoother, more precise surface finishes.

03

Reduced Built-Up Edge (BUE):

The smooth diamond surface and low friction help minimize material adhesion (e.g., when machining aluminum or copper alloys).

04

Machining of Hard Materials:

Enables effective machining of materials with hardness up to HRC 60+ (e.g., hardened steels, cemented carbides, ceramics, metal matrix composites), which is challenging for standard carbide tools.

05

Products Applications

● Non-Ferrous Metals & Alloys: Especially high-silicon aluminum alloys (e.g., pistons, engine blocks), copper alloys (brass, bronze), magnesium alloys. The coating effectively resists wear from hard silicon particles or abrasive constituents.

● Non-Metallic Materials:

Graphite Electrodes: The preferred tool for graphite machining, exhibiting minimal wear.

Carbon Fiber Reinforced Polymers (CFRP): Resists severe abrasion from carbon fibers, reducing delamination and fraying.

Glass Fiber Reinforced Plastics (GFRP): Resists abrasion from glass fibers.

Ceramics: Machining engineering ceramics and refractory materials.

Reinforced Engineering Plastics/Polymers: Plastics containing glass fibers, carbon fibers, mineral fillers, etc.

● Pre-Hardened/Through-Hardened Steels: Diamond coated carbide end mills Steels in the HRC 45-65 range.

● Cemented Carbides: Machining carbide blanks or workpieces.

● Metal Matrix Composites (MMCs): e.g., Aluminum Silicon Carbide (AlSiC).

● Abrasive Woods: e.g., Medium-Density Fiberboard (MDF), laminates, wood containing glue and minerals.

Selection Considerations

1. Confirm Workpiece Material: Diamond coated carbide end mills Must be non-ferrous or highly abrasive non-metallic.

2. Coating Type: Options include microcrystalline diamond (MCD), nanocrystalline diamond (NCD), etc., optimized for different materials and applications.

3. Coating Quality: Adhesion strength, uniformity, and surface smoothness are key indicators.

4. Substrate Grade: Requires a carbide grade compatible with the coating process, offering sufficient toughness.

5. Tool Geometry: Edge preparation, helix angle, rake angle, etc., must be designed for the specific material and operation.