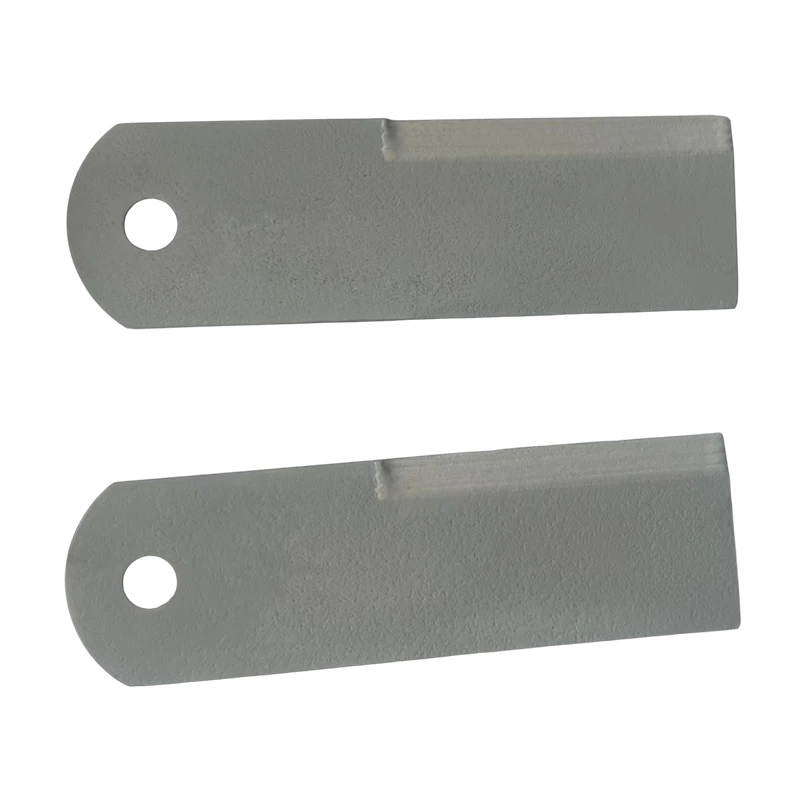

Description

A harvester blade, often referred to as a sickle bar or cutter bar, is a critical component of a harvesting machine, particularly in combine harvesters and reaper binders. Its primary function is to cut through crops such as wheat, barley, and corn during the harvest process. Harvester blades are designed to be strong, sharp, and durable, capable of withstanding the rigors of cutting through dense plant material without frequent replacement.

Advantages of Harvester Blade

High hardness

The blade needs to be hard enough to cut crops to ensure a neat cut.

High toughness

The blade needs to withstand great impact and vibration during work and needs to have sufficient toughness to ensure that it does not break or deform.

Wear resistance

The harvester blade needs to have strong wear resistance to ensure a long service life.

Efficiency

The harvester blade can simultaneously harvest, thresh and clean grain crops, greatly increasing the speed and efficiency of the harvesting process compared to traditional manual methods.

Labor savings

The harvester blade significantly reduces the manual labor required for harvesting, as one machine can do the work of many farm workers.

Increased productivity

By automating and streamlining the harvesting process, the harvester blade enables farmers to cover more land in less time, thereby increasing overall productivity and yields.

Effortlessly mince, chop, grind and blend a variety of ingredients for easy meal preparation or final touches

Perfect for garlic, onion, zest, spices, herbs, cheese, bacon crumbles, nut chopping, chocolate, dressings, sauces and spreads

Woodworking forming blades are essential tools for any woodworking professional or hobbyist. These blades are used for shaping and forming wood, creating intricate designs, and achieving a smooth finished product.

Woodworking Steel Planer Blade

One major advantage of Woodworking steel planer blade is their durability. This tool is made of high-quality steel and can withstand a large amount of use with a long service life. This means you don't have to worry about replacing the blades after each project, nor do you have to worry about purchasing new blades due to blade wear. With proper maintenance and upkeep, steel planer blades can continue to provide excellent results in the coming years.

Crusher blade using flat design, divided into the moving knife and the fixed knife, usually a pair of grinder blades are 5 pieces, consists of 3 pieces of grinding moving knife and 2 pieces of fixed knife, through moving knife's high speed rotating and stationary knife's shearing to crush plastic materials, can adjust grinding knife to control the size of crush granule.

PE film slitting blade is a crucial component in the process of slitting plastic films. It plays a significant role in ensuring that the cut edges of the film are precise, smooth and without any burrs. With the rapid advancement of technology, there has been an increased demand for high-quality slitting blades that can meet the growing needs of various industries.

Semiconductor punching blades are an essential tool for the manufacturing of semiconductor products. These blades are specifically designed to cut through the hard and delicate materials used in the fabrication process.

Laminating machine blade machines are essential for keeping important documents and papers safe and secure from any damages. They use a blade to cut the laminating film to the appropriate size and shape. The blade is a crucial component in a laminating machine as it ensures that the lamination process is precise and effective.

Easy-tear cutting blade Widely used in mechanical manufacturing and processing industries and fields such as papermaking, packaging, printing, film, new materials, rubber and plastic, food, chemical industry, light textile, metallurgy, landscaping and woodworking, electronics and appliances, construction engineering, automobiles and ships, aerospace, etc.

Why Choose Us

Factory

The company is a professional industrial cutting tool production and processing enterprise. The company team has 15 years of industry experience. Through years of continuous accumulation and exploration, it has successfully completed technological transformation.

High-quality service

We insist on returning the support and love of our customers and friends from all parties with stable, reliable, economical, durable and high-quality products.

Customized service

Our team of experts will work closely with you to understand your needs and provide tailor-made solutions to meet your expectations.

Competitive price

We are confident in the quality of our products and are willing to provide you with long-term technical service support.

Types of Harvester Blade

Multi-purpose knives

Multi-purpose knives are multi-purpose hand-held tools equipped with retractable or replaceable blades.

Circular knives and blades

These knives feature a circular blade mounted on a rotating shaft and come in a variety of shapes and sizes.

Straight knives and blades

Flat, usually with a sharp edge on one side, making them useful for chopping, slicing, dicing, scoring, and trimming. They can be made from materials such as stainless steel and high-speed steel.

Slitting blades

Designed for precise, consistent slitting or scoring of materials such as paper, film, and foil.

Guillotine knives

Cutting tools specifically designed for clean, accurate, efficient, consistent cutting.

Rotary blades

Description: Consists of a cylindrical cutting wheel with a sharp edge, ideal for cutting fabric, leather, and paper.

Cutting blades

Come in a variety of shapes and sizes and are often used with cutting machines.

Granulator blades

Designed for shredding and granulating plastic materials.

Material of Harvester Blade

High speed steel blades

In certain manufacturing practices, the nature of the work will require the production or packaging line to be in constant use. In these situations, you need a blade that will work continuously without service disruption and one that can also withstand heat.

Tungsten carbide tipped

These blades are very strong and have the capacity to easily handle significant loads. They are sharp, durable and long-lasting, offering precision cuts and reliability. The main body of the blade is made from standard steel, but the edges feature small areas of carbide which have been brazed onto the blade.

Carbide blades

A high-quality carbide blade will retain its edge for between ten and twenty times longer than average tool steel which is a significantly longer period of time, maximising their working life. When it comes to long production runs, these blades would be ideal, particularly where machine downtime would have a detrimental impact on operations.

Stainless steel

This type of blade will resist corrosion which is important for production and packaging. This property is achieved through the addition of chromium.

420

This steel grade will resist stains, but it is quite a soft material, and it won't offer the longevity that you may need. It will lose its edge quite quickly meaning that frequent changes will be required. 420 stainless steel has a higher carbon content, and it's hardness can be increased through heat treatment. This grade of steel is commonly used in the vertical form fill and seal operations or in packaging where blades require regular replacement.

440B

A steel grade made from high carbon stainless steel. It is hardened to a greater degree in comparison with 420 which means that it offers more strength and resistance to everyday use.

440C

This grade of steel is stronger still because of its higher carbon content. It offers a high level of hardness but is slightly less resistant to corrosion than 440B steel grade. It does, however, hold its sharp edge much better and is able to resist stains much more effectively.

How to Maintain Harvester Blade

Clean the cutter regularly

The cutter is one of the core components of the harvester. It should be cleaned and oiled regularly to ensure the sharpness and service life of the cutter.

Replace the cutter regularly

The cutter is a consumable part and should be replaced regularly according to the usage to ensure the quality and efficiency of harvesting.

Check the machine regularly

The harvester is an important agricultural machinery and equipment. The wear degree of each component and the operating condition of the machine should be checked regularly to find and solve problems in time to ensure the normal operation and service life of the machine.

Process of Harvester Blade

Material selection

Common materials for harvester blades include high-speed steel, carbon steel and alloy steel. When selecting materials, the hardness, wear resistance, toughness and other indicators of the blade need to be considered. Generally speaking, high-speed steel harvester blades are more wear-resistant, but the price is higher; carbon steel is relatively cheap but not as wear-resistant as high-speed steel.

Processing

After selecting the right material, the blade needs to be processed. During the processing, various machine tools and equipment, such as drilling machines and lathes, are required to process the blanks into parts with blade shapes. During processing, the size and surface quality need to be strictly controlled to ensure the accuracy and firmness of the blade.

Heat treatment

Heat treatment is an important part of blade production. It can improve the hardness and toughness of the blade and prevent deformation and cracks after long-term use of the blade. Common heat treatment methods include quenching, tempering, carburizing, etc.

Surface treatment

Surface treatment is to protect the surface of the blade and prevent rust and corrosion on the surface of the blade. Common surface treatment methods include metal plating and spraying.

Assembly

After the harvester blade is made, it needs to be assembled. This step requires strict control of the position and angle of the blade to ensure that the contact area between the blade and the mower is maximized.

How to Choose a Harvester Blade

Cutting material

The type of material being cut is a key factor in choosing the right harvester blade. Different materials have different properties, such as hardness, thickness, and abrasiveness, which can affect the type of harvester blade required.

Blade hardness

The hardness of the blade material can affect the durability of the harvester blade. Hard materials, such as carbide or ceramic, are ideal for cutting abrasive materials, while soft materials, such as high-speed steel or tungsten carbide, are better suited for cutting softer materials.

Blade geometry

The blade geometry can affect the precision and accuracy of the cut. There are different types of blade geometries available, such as straight, wavy, and rounded, which are suitable for different applications.

Blade coating

The coating on the blade can affect its wear resistance and lubricity. There are different coatings available, such as diamond, titanium nitride, and chrome, which provide different levels of wear resistance and lubricity.

Machine compatibility

The harvester blade must be compatible with the harvester being used. Different machines have different specifications for blade thickness, diameter, and mounting type, which must be considered.

Cutting speed and volume

The cutting speed and volume required for the application can also affect the choice of harvester blade. For high-speed cutting operations, a harder, more wear-resistant blade material may be required, while for low-volume cutting, a softer blade material may be sufficient.

Supplier reputation

It is important to work with a reputable supplier who can provide guidance and advice on selecting the right harvester blade for your specific needs. Look for a supplier with a track record of providing high-quality products and excellent customer service.

The harvester blade mechanism mainly drives the blade to rotate through the drive device to achieve the purpose of cutting crops. Specifically, the drive device of the harvester outputs a certain amount of power to drive the transmission device to rotate, thereby driving the various components to work together.

As the core component of the harvester blade mechanism, the blade uses its sharp edge to cut the crop into a certain length of straw. Since the blade is in a high-speed rotating state, there are also strict requirements for the material and hardness of the blade. Common blade materials include high-speed steel, cemented carbide, etc.

In order to ensure the life and cutting effect of the blade, the harvester blade mechanism is also equipped with an adjustment device and a protection device. The adjustment device can adjust the cutting depth of the blade, and the protection device can stop the cutting work in time when the blade encounters external obstacles to avoid damage to the blade.

Detailed Steps for Replacing Harvester Blades

Preparation

Replacing the blade requires the preparation of the required tools, usually wrenches, tensioners and other tools. Before replacing the blade, all power supplies of the harvester need to be disconnected and the machine switch turned off to ensure safe operation.

Loosen the old blade

Before replacing the blade, you need to loosen the old blade first. Use a wrench to loosen the nut locked on the blade screw, and use a tensioner to gently pull the blade outward as needed to avoid damaging the harvester main shaft. You also need to pay attention to safety.

Install the new blade

After removing the old blade, you need to install the new blade correctly according to the instructions provided by the harvester manufacturer. First, align the new blade with the main shaft, then tighten the nut with a wrench, and fix the blade with a tensioner. When installing the new blade, be careful not to install it too tight or too loose to avoid affecting the cutting effect.

Adjust the blade position

After replacing the blade, you need to adjust it according to the harvester's instruction manual. Usually, you need to adjust the blade position and height to ensure the best cutting effect. During the adjustment process, you need to pay attention to keeping the cutting smooth and not wearing the blade excessively.

Precautions

When replacing the harvester blade, you need to pay attention to the following points: First, safety first, the machine needs to be turned off during operation to ensure safety; second, the blade model must be selected to avoid mismatching; third, when adjusting the blade position, it needs to be kept stable to avoid blade swinging.

What Are the Trends and Development Directions of Harvester Blade in the Market

These blades are produced using wear-resistant materials, special coatings, and heat treatment technologies. They are designed specifically to meet the needs of modern agriculture, with surface options suitable for a variety of load and wear conditions, ensuring long-term and safe use of the blades. Technological innovations in harvester blades include advanced coating processes such as laser cladding and thermal spraying. These processes increase the sharpness and durability of the blades while maximizing wear resistance, allowing the blades to perform well even in challenging agricultural conditions.

Each harvester blade is specially hardened and optimized to provide the best agricultural technology performance. This customization enables agricultural machinery to operate longer and more effectively, directly affecting the efficiency and quality of agricultural production.

In short, harvester blades are innovative and technologically advanced products that improve efficiency and performance in the agricultural sector. These blades enable agricultural machinery to operate longer with less maintenance, saving farmers time and costs.

Our Factory

Ganzhou Big Brother Cutting Tools Co., Ltd. is a professional manufacturer and processor of industrial cutting tools. The company team has 15 years of industry experience and has successfully completed technological transformation through years of continuous accumulation and exploration.Also skilled in researching and producing non-standard cutting tools, molds, etc The main products include: packaging machine knives, non-standard blades, industrial knives, food machine knives, woodworking planers, alloy blades, precision knife molds, shredder knives, agricultural machinery knives, and various mechanical cutting tools for mass production and non-standard customization.

FAQ

Q: What is a harvester blade?

Q: What materials are harvester blades made of?

Q: How are harvester blades attached to the cutting unit?

Q: What is the difference between a sickle bar and a disc header harvester blade?

Q: How does the blade length affect harvesting performance?

Q: What is the importance of blade sharpness in harvesting?

Q: How often should harvester blades be replaced?

Q: Can harvester blades be sharpened?

Q: What safety precautions should be taken when handling harvester blades?

Q: How do weather conditions affect the performance of harvester blades?

Q: What maintenance is required for harvester blades?

Q: What are the environmental impacts of using harvester blades?

Q: Are there any alternative cutting methods to harvester blades?

Q: Can harvester blades be recycled?

Q: How do harvester blades contribute to crop yield?

Q: What is the cost of harvester blades?

Q: What are the common issues with harvester blades?

Q: How do harvester blades affect the resale value of agricultural machinery?

Q: Can harvester blades be customized for specific crops?

Q: What is the process of harvester?