Description

Products Description

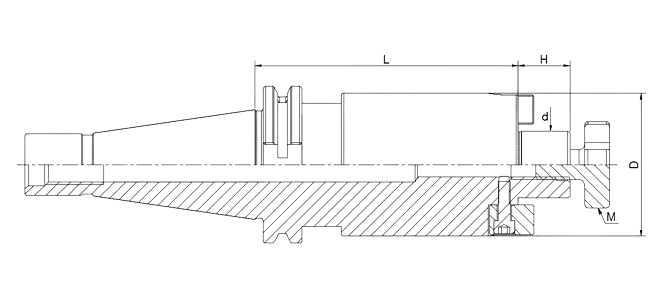

A Hydraulic End Mill Holder is a high-precision collet chuck that utilizes hydraulic pressure to clamp cutting tools (like end mills) accurately and uniformly. It contains a sealed internal hydraulic chamber. Increasing the oil pressure causes the holder's inner wall to deform elastically and evenly, thereby gripping the tool shank with immense force.

Products Specification

| |||||

| Size | d | D | L | H | M |

| SK40-FMB16-45 GOST | 16 | 38 | 45 | 17 | M8 |

| SK40-FMB22-45 GOST | 22 | 48 | 45 | 19 | M10 |

| SK40-FMB27-40 GOST | 27 | 58 | 40 | 21 | M12 |

| SK40-FMB32-55 GOST | 32 | 78 | 55 | 24 | M16 |

| SK40-FMB40-55 GOST | 40 | 88 | 55 | 27 | M20 |

| SK50-FMB16-40 GOST | 16 | 38 | 40 | 17 | M8 |

| SK50-FMB22-45 GOST | 22 | 48 | 45 | 19 | M10 |

| SK50-FMB27-45 GOST | 27 | 58 | 45 | 21 | M12 |

| SK50-FMB32-50 GOST | 32 | 78 | 50 | 24 | M16 |

| SK50-FMB40-55 GOST | 40 | 88 | 55 | 27 | M20 |

How It Works

The working principle of a Hydraulic End Mill Holder can be broken down into a few simple steps:

Inject Hydraulic Oil: The holder has one or more filling holes (pressure screw ports) on its side or end. A dedicated wrench is used to tighten the pressure screw, which drives an internal piston.

Generate Uniform Pressure: The piston compresses the specialized, incompressible hydraulic oil inside the chamber. This oil transmits the pressure uniformly to the entire inner sleeve surrounding the tool.

Elastic Deformation and Clamping: Under this uniform hydraulic pressure, the holder's thin-walled inner sleeve undergoes minimal, even radial elastic deformation. This allows it to grip the tool shank with 360-degree contact and high precision.

Tool Release: To change the tool, simply loosen the pressure screw with the wrench. The internal pressure is released, the thin-walled sleeve returns to its original shape, and the tool can be removed easily.

Comparison with Other Common Tool Holders

| Feature | Hydraulic Holder | Collet Chuck | Heat-Shrink Holder | Set Screw (Weldon) Holder |

|---|---|---|---|---|

| Clamping Accuracy | Exceptional (≤ 3µm) | Good (Depends on collet/nut quality) | Highest (≤ 3µm) | Poor |

| Damping Ability | Excellent (Hydraulic damping) | Fair | Good (Monolithic design) | Poor |

| Gripping Force | Very Strong | Medium (Prone to slippage) | Strong | Strongest (But damages shank) |

| Versatility | High (One holder fits a range of sizes) | Highest (Change collets) | Low (One holder, one size) | Low (One holder, one size) |

| Ease of Use | Convenient (Just a screw) | Convenient | Requires heating equipment | Convenient |

| Cost | High | Low to Medium | High (Requires heater) | Low |

| Tool Shank Damage | None | None | None (Heat may affect coating) | Yes (Creates indentations) |

Products Applications

Hydraulic End Mill Holder are suitable for the following high-demand processing occasions:

1. High-Speed Machining (HSM): Requires exceptional balance and stability at high RPM.

2. Finishing & Ultra-Finishing: Essential for achieving superior surface finishes (Ra values) in mold cavities and precision components.

3. Deep Cavity Machining: Their damping characteristics are critical for long-reach applications to prevent chatter and tool deflection.

4. Hard-to-Machine Materials: When machining materials like titanium or Inconel where vibration is a primary concern, the damping effect is a major advantage.

5. Using Expensive Tools: Ideal for non-marring clamping of costly solid carbide end mills, diamond tools, etc.

Technological advantages

1.Over 60 CNC grinding machines.

2.10+ 5-axis CNC machining centers.

3.5 wire-cut machines.

4.10 precision grinding machines.

5.Over 30 other specialized equipment (such as material testing, spectrometers, hardness testing, and 3D testing).