Description

Product Introduction

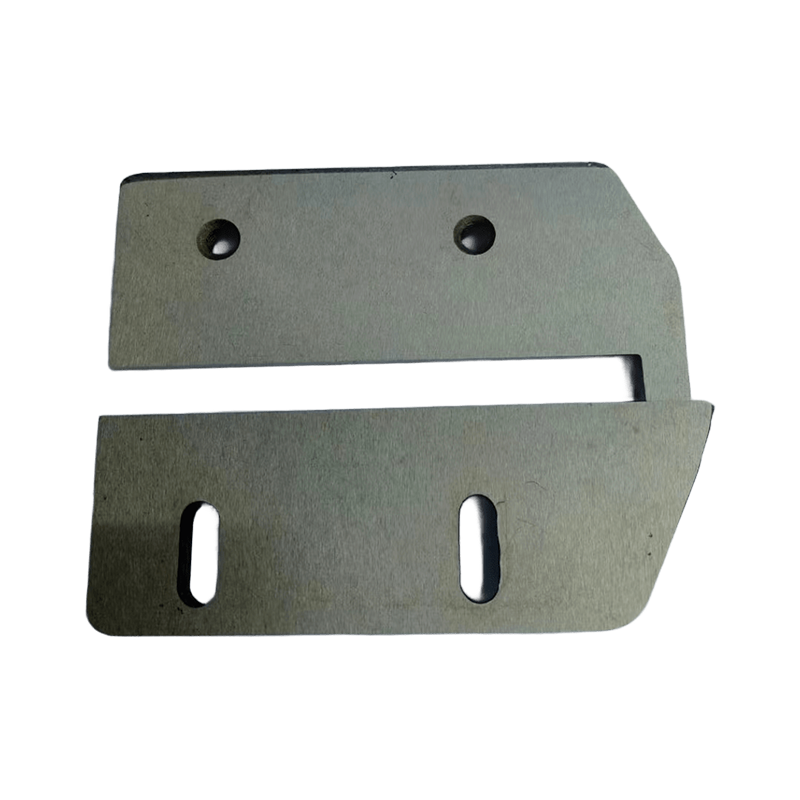

Rapid cutter

The cutter is a specialized tool designed for cutting medicine bag packaging, made of high-quality materials such as high-speed steel.

The blade of the Medicine Bag Packaging Cutter is sharp and burr-free, ensuring precise and consistent cutting through precise cutting holes and positioning holes. It is suitable for various sizes of medicine bags, achieving efficient and accurate cutting of medicine bags.

Product Features

01 Waterproof Performance

The surface of the cutter is covered with nano-grade Teflon waterproof coating, which is processed by vacuum sputtering process and closely adheres at the molecular level to form a waterproof barrier with a thickness of 0.05-0.1 microns. In an environment with a relative humidity of 95%, it can prevent water erosion, rust and corrosion.

02 High-precision Cutting

The edge accuracy of medicine bag packaging cutter is controlled within ±0.01 mm. When cutting 0.05-0.1 mm thick medicine bags, the incision is neat and smooth, which meets the strict requirements of medicine packaging for cutting accuracy and prevents damage to medicine bags and leakage of medicines.

03 High safety

The materials used in the medicine bag cutter are non-toxic and harmless, and they have excellent durability to prevent fragments or debris from forming during use. Additionally, the product undergoes rigorous quality inspection before leaving the factory to ensure there are no sharp edges or defects, guaranteeing safe usage.

04 Easy to operate

medicine bag packaging cutter is lightweight, compact size. The cutting edge is sharp, allowing you to easily cut materials by simply placing them under the cutter.The cutting speed may range from several times per second to more than a dozen times per second

Product Application

Pharmaceutical Industry

The medicine bag packaging cutter is mainly used to cut continuous medicine bag packaging materials into specified sizes to form independent medicine bag packaging.

Food Packaging Field

The medicine bag packaging cutter is used to cut rolls of food packaging bag materials into individual packaging units, such as snacks, desiccants, etc., so that the packaging size meets the product specification requirements.

Daily Chemical Packaging

In the packaging process of daily chemical products, the cutter is responsible for cutting small packaging bags such as shampoo and shower gel, separating them from large rolls of packaging materials to ensure the standardization and integrity of the packaging.

daily maintenance

cleaning

After each use, wipe the cutter with a clean soft cloth to remove residual powder and debris to prevent corrosion.

lubrication

Apply a proper amount of lubricant to the rotating part of the medicine bag packaging cutter regularly to ensure its flexible rotation.

inspection

Check whether the cutter blade is worn or notched. If so, repair or replace it in time to ensure the cutting quality when it is used next time.

Record

Detailed records of each maintenance session, including time, content, and identified issues, facilitate tracking and preventive maintenance.

FAQ

01.Q: Are you a trading company or a manufacturer?

02.Q: May I request a sample before placing my order?

03.Q: What are your terms of payment?