Description

Product introduction

A non-standard blade is a blade that is customized to meet specific needs or industry standards. It is different in size, shape, material or processing method compared to a regular standard blade. When using a non-standard blade, the operator should first select the appropriate blade type according to the material and processing process being processed, and then ensure that the blade is firmly installed and adjusted to the appropriate working position.

Product features

High Hardness

Our non-standard blades are made of nano-grain tungsten carbide material with a hardness of HRA 93.5-94.8. This is 25-30% higher than traditional high-speed steel blades and 8-12% higher than ordinary carbide blades. When cutting hardened steel with a hardness of 40-50 HRC, our blades can continuously process for 180-220 minutes, while ordinary blades can only maintain 60-90 minutes.

Wear Resistance

By adding alloying elements such as 8% tungsten, 5% molybdenum and 2% vanadium, our non-standard blades have high wear resistance. After 8 hours of continuous machining of 4140 quenched and tempered steel, the tool wear was only 0.12mm, which is 73% lower than that of ordinary high-speed steel tools.

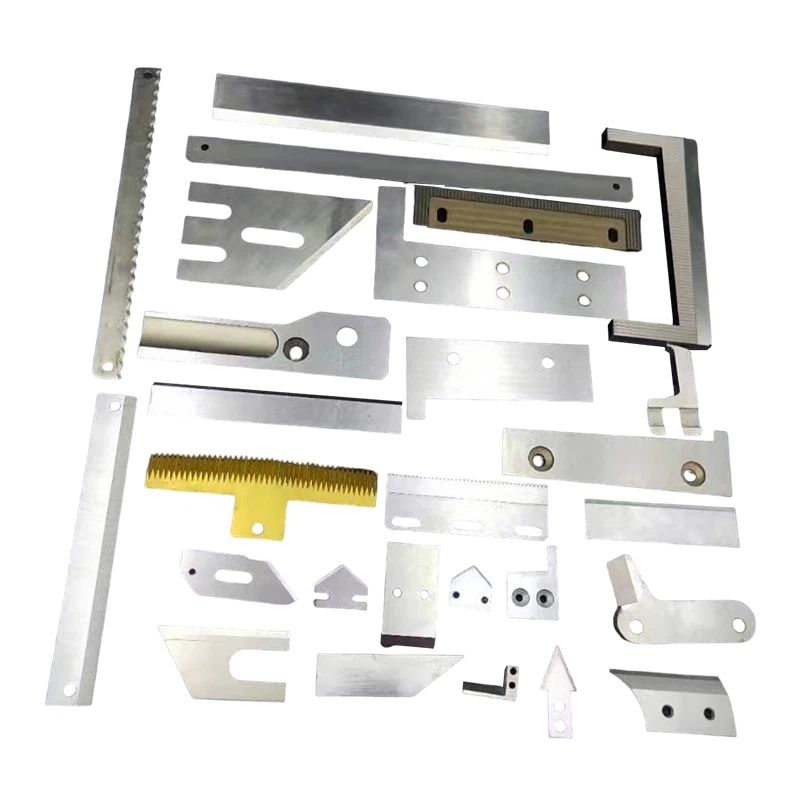

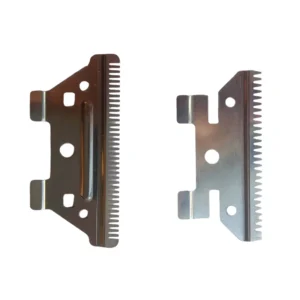

Diversified Shapes

Our non-standard tools offer more than 20 shape designs, including straight, serrated, T-shaped, L-shaped, etc. This allows us to provide customers with tailor-made solutions to meet more than 90% of machining needs. For example, serrated tools are suitable for cutting soft materials, while T-shaped and L-shaped tools are more suitable for metal processing or mold making.

FAQ

Q: Why choose us?

Q: Can I get a sample before placing an order?

Q: Do you offer service of signing trade secret protectin contract ?