Description

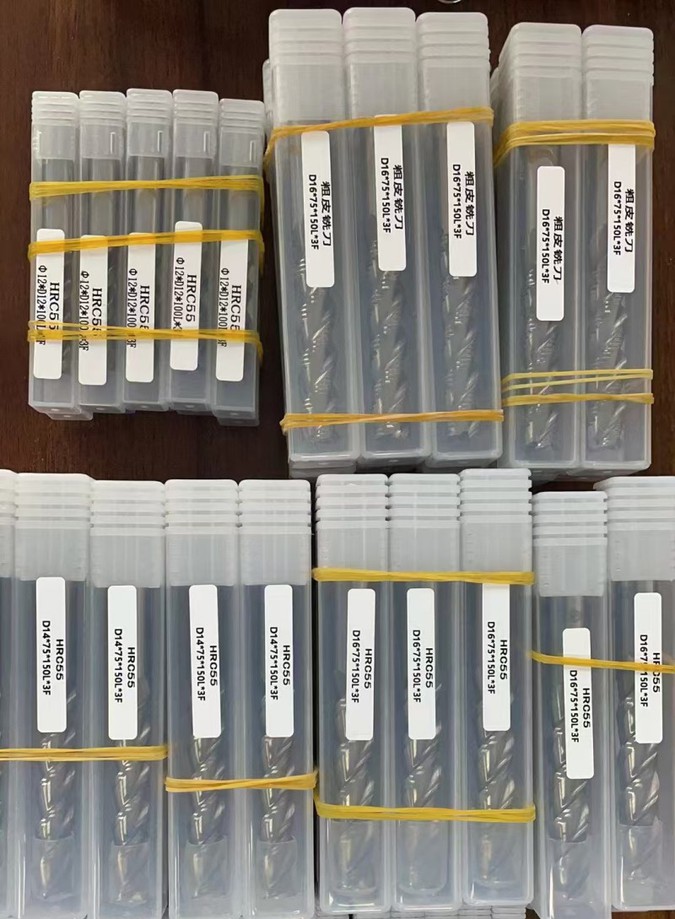

Products Description

Roughing and Finishing End Mills are specialized types of cutting tools used in milling operations (like CNC machining) for distinct stages of material removal. Here's a breakdown of their differences and purposes:

Rapid removal of large volumes of material to get close to the final shape/dimensions.

1. Key Features:

● Serrated Teeth (Corn Cob Design): Multiple, shallow cutting edges with pronounced gullets (spaces) between them.

● Chip Breaking: The serrations break long chips into small, manageable segments. This prevents chip wrapping around the tool, reduces heat buildup, and allows deeper cuts.

● Reduced Vibration: The interrupted cutting action dampens vibrations, allowing higher feed rates and depths of cut without chatter.

● Lower Helix Angles: Often have lower helix angles (e.g., 30°-35°) for increased strength and rigidity.

● Robust Design: Built to withstand high cutting forces and shock loads.

2. Benefits:

● High Material Removal Rate (MRR)

● Excellent chip clearance and evacuation.

● Longer tool life under aggressive cutting conditions.

● More stable cutting with less vibration.

3. Resulting Surface: Leaves a relatively rough surface finish with characteristic scallop marks from the serrations. Requires further finishing.

4. Common Names: Corncob mills, Hoggers, Ripper mills.

Achieve the final dimensions, tight tolerances, and a smooth surface finish.

1. Key Features:

● Smooth Teeth: Fewer cutting edges (typically 4-6 for square end mills) that are continuous and sharp.

● Precision Ground: Edges are precisely ground for accuracy and sharpness.

● Higher Helix Angles: Often have higher helix angles (e.g., 40°-45° or even higher like 50°-60° for aluminum) for shearing action and smoother cuts.

● Variety of Geometries: Include square end, ball nose (for contours), corner radius (for strength and blending), and specialized profiles.

● Chip Evacuation: Designed for clean cutting with less focus on massive chip breaking.

2. Benefits:

● Excellent surface finish.

● High dimensional accuracy and tight tolerances.

Clean, precise cuts with minimal burring.

● Ability to machine fine details and walls.

3. Resulting Surface: Produces the desired final smooth or semi-smooth surface.

4. Common Names: Finishers, Precision end mills, Ball nose mills (a type of finisher).

Products Specifications

Relevant chucks are also available.

The Solid End Mills also can be made according to your own specifications.

| |||||

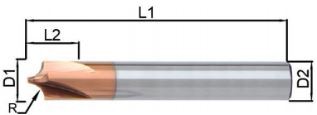

| Internal R | Dia. of Cut D1 | Length of Cut L2 | Overall Length L1 | Dia. of Shank D2 | Teeth F |

| 0.3 | 2.4 | 6 | 50 | 3 | 4 |

| 0.4 | 2.2 | 6 | 50 | 3 | 4 |

| 0.5 | 2.0 | 6 | 50 | 3 | 4 |

| 0.5 | 3.0 | 8 | 50 | 4 | 4 |

| 0.75 | 2.5 | 8 | 50 | 4 | 4 |

| 1.0 | 2.0 | 8 | 50 | 4 | 4 |

| 1.5 | 3.0 | 12 | 50 | 6 | 4 |

| 2.0 | 2.0 | 12 | 50 | 6 | 4 |

| 2.5 | 3.0 | 16 | 50 | 8 | 4 |

| 3.0 | 2.0 | 16 | 50 | 8 | 4 |

| 4.0 | 2.0 | 20 | 60 | 10 | 4 |

| 5.0 | 2.0 | 24 | 60 | 12 | 4 |

| 6.0 | 2.0 | 28 | 80 | 14 | 4 |

| 7.0 | 2.0 | 32 | 100 | 16 | 4 |

Typical Machining Sequence

1. Roughing: Use a Roughing End Mill to quickly remove the bulk of the material, leaving a small, consistent amount of stock (e.g., 0.010" - 0.030" or 0.25mm - 0.75mm) for finishing.

2. Finishing: Use a Finishing End Mill to cut away the remaining stock precisely, achieving the final dimensions, tolerances, and surface finish.

Material Considerations

Roughing And Finishing End Mills Both types come in various substrate materials (HSS, Cobalt, Carbide) and coatings (TiN, TiAlN, ZrN, etc.) optimized for cutting specific materials (steel, aluminum, titanium, plastics, etc.).

The choice of coating and substrate significantly impacts tool life and performance in both roughing and finishing.

Company Strength

Ganzhou Big Brother Cutting Tools Co., Ltd. is a professional manufacturer and processor of industrial cutting tools. Our factory covers an area of 5000 square meters.The company team has 15 years of industry experience. We have more than 100 pieces of machinery and equipment. Through years of continuous accumulation and exploration, we have successfully completed technological transformation.