Description

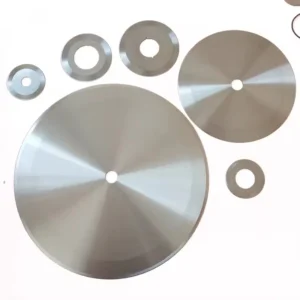

Round paper cutting blade is a useful tool that can make precise cuts on paper with ease. It is a perfect tool for those who work with paper on a regular basis or those who enjoy paper crafting as a hobby.

One of the great things about a round paper cutting blade is its versatility. It can be used for a variety of cutting tasks, including straight lines, curves, and intricate shapes. Whether you need to make a greeting card, a scrapbook page, or a paper model, a round paper cutting blade can help you achieve the desired result.

Advantages of Round Paper Cutting Blade

Precision

Round paper cutting blade make clean, precise cuts through even the thickest papers. With the right blade, you can quickly achieve straight, beautifully cut lines that are perfect for various projects.

Efficiency

Paper blades can save time and increase productivity by making the cutting process faster and more efficient. They also prevent paper tearing.

Versatility

Offer a wide range of blade sizes and shapes, allowing you to find the perfect tool for your paper crafting projects.

Durability

Round paper cutting blade are designed to resist wear and tear better than regular blades. It means you won't have to replace them as often, saving you both time and money in the long run.

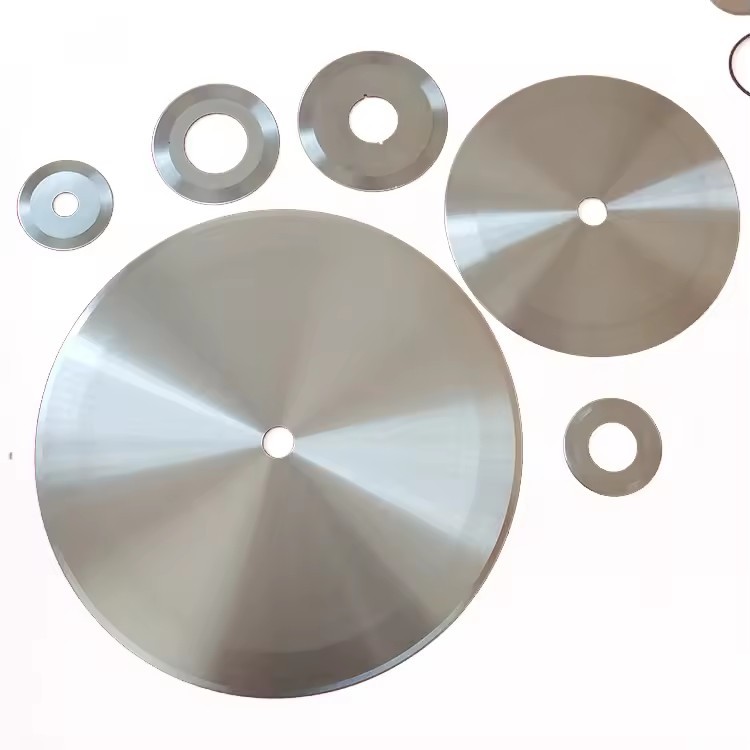

Round Packaging Machinery Blade

Round packaging machinery blade is an essential tool used in the packaging industry. It is responsible for ensuring that products are properly packaged and prepared for shipping. This blade is designed to be durable and efficient, allowing businesses to cut down on their production time and increase their output.

Circular Slitter Blades Applicable industries: Hotels, clothing stores, building materials stores, manufacturing factories, machinery maintenance stores, food and beverage factories, farms, household use, retail, food stores, printing stores, construction engineering, energy and mining, food and beverage stores, advertising companies

Rubber cutting blades are an essential tool for many industries that work with rubber materials. These blades are designed to cut through rubber with ease and precision, allowing for accurate cuts that ensure the material is properly sized for its intended use. With the right rubber cutting blade, workers can significantly improve their efficiency and accuracy in their work.

Why Choose Us

Factory

The company is a professional industrial cutting tool production and processing enterprise. The company team has 15 years of industry experience. Through years of continuous accumulation and exploration, it has successfully completed technological transformation.

High-quality service

We insist on returning the support and love of our customers and friends from all parties with stable, reliable, economical, durable and high-quality products.

Customized service

Our team of experts will work closely with you to understand your needs and provide tailor-made solutions to meet your expectations.

Competitive price

We are confident in the quality of our products and are willing to provide you with long-term technical service support.

The procedure for changing a blade will vary depending on the make and model of the cutter. But regardless of the type of cutter, most operator accidents occur during the knife-changing operation. It is important for every operator to develop good safety habits, follow the manufacturer's procedures, and provide a safe machine.

The knife on a 45-inch cutter weighs about 40 pounds. It doesn't take much imagination to know what could happen if the knife slipped and pinched a hand or finger.

Modern cutters have built-in safety devices to reduce this danger. Even so, carelessness can render even the best safety devices ineffective.

Regardless of the age and brand of the cutter, following these blade sharpening safety tips should reduce the risk of an accident:

Before removing a dull knife from the machine, place an empty knife plate on the cutter table. Then, secure the knife to the knife plate immediately after removing it.

Always use the proper knife handle to ensure proper installation.

Never leave the sharp edge of a knife unnecessarily exposed to accidental contact or collision.

Know and follow the manufacturer's procedures when changing knives.

Remember to minimize handling of unprotected knives. By insisting that operators follow proper procedures for maintaining paper cutter blades, you can minimize operator hazards, save time and money, and improve the quality of work.

Types of Round Paper Cutting Blade

Circular blades

Choose our circular blades for multiple applications, from scoring to perforating. Our engineers tailor these knives to your specifications. Whether you want a toothless or toothed blade, we can manufacture it. We also offer different materials to choose from as well as tooth configurations or edge styles based on your blade type.

Guillotine cutter knives

Guillotine knives are commonly used for paper cutting applications. Our guillotine knives feature a handful of tooth configurations to achieve the precision cuts you need when cutting paper.

Cutoff blades

Incorporate the precision and quality of our cutoff blades into your paper operation. We offer these specialty blades for paper cutting in several materials, including ceramic and 52100, and we can configure their edges to your unique needs. If you already have guillotine knives but they're underperforming or giving you problems, our team can test them for free.

Straight blades

Get some of the cleanest, most efficient cuts with our cost-effective straight blades. Whether you need to slice, slit, score, crease, cut or trim paper, you can depend on these paper cutting blades, which are ready for customization. Choose from materials that range from high carbon to d-2, as well as edge configurations that include double blunt and double sharp.

Paper tube blades

Handle tubes of paper with our paper tube blades. These industrial machine knives feature a chrome vanadium steel build as well as a 49-52 rockwell hardness rating. Our team can provide custom tooth grinding and blade widths for these knives as well as same-day shipping for an in-stock replacement.

Application of Round Paper Cutting Blade

![]()

Textile industry

In textile manufacturing and processing, circular blades are used to cut cloth, fabric, leather, etc.

![]()

Cutting paper

Circular paper cutters are widely used in the office, printing, and packaging industries, and can effectively cut various types of paper, such as a4 paper, business cards, posters, etc.

![]()

Cutting plastic

Circular paper cutters can also cut various types of plastic products, such as plastic bags, PVC boards, foam boards, etc.

![]()

Cutting leather

Circular paper cutters can also be used to cut leather products, such as shoes, belts, wallets, etc.

A Step-by-Step Guide to Using a Round Paper Cutting Blade

Familiarize yourself with your round knife

Before you start cutting, take some time to learn about the components of your circle cutter, including the blade, measuring rail, and cutting base. Please read the manufacturer's instructions to make sure you understand any specific features or safety precautions.

Prepare your workspace

Place a cutting mat to protect your work surface. Not only does this prevent damage to the tabletop, but it also provides a smooth, sturdy base for cutting.

Choose material and size

Choose the material you want to cut the circle from. Decide on the size of the circle you want to create, and set your circle knife's measurement guide accordingly. Some round milling cutters offer adjustable sizes for flexibility.

Mark the center (optional

If you want to cut a circle with a specific center point, use a pencil to mark the center on the material. This step is especially useful for projects where alignment is critical.

Positioning the tool

Place the circular cutter on the material, aligning the center of the cutter with the marked center of the circle. Make sure the measurement guide is set to your desired radius.

Start cutting

Press firmly on the base of the cutter to hold it firmly in place. Then, turn the knife smoothly clockwise or counterclockwise depending on your preference and the design of the knife.

Follow through

As you rotate the cutter, its blades cut through the material cleanly and evenly. Keep your hand steady and the pressure even to achieve smooth circles.

Lift the cutter

Gently lift the knife away from the material to reveal a perfectly cut circle. If multiple circles need to be cut, repeat the process by realigning the cutter and adjusting the measuring guides as necessary.

Clean up

Dispose of all waste and clean your workspace. Proper maintenance of your round knife and cutting mat will ensure their longevity.

Material of Round Paper Cutting Blade

Carbon tool steel

Carbon steel is used for low-speed machining operations. Abrasion resistance and the ability to keep a sharp cutting edge are two advantages of high carbon steels. Carbon tool steels have high machinability. Carbon steel starts melting at a temperature of approx. 180 – 250 degrees. As a result, it is unable to operate at high temperatures.

High-speed steel (HSS)

High-speed steel is widely used in machining operations. HSS tools are used to make complex-shaped tools like drills, reamers, taps, dies, and gear cutters. They are robust and ideal for interrupted cutting. HSS loses its hardness at a temperature of approx. 600-650 degrees. As a result, a coolant should be applied to extend the tool's life. It can be re-sharpened and used multiple times.

Cemented carbide

Cemented carbide cutting tool consists of tantalum, tungsten, and titanium carbide with cobalt as a binder. Carbide tools are extremely tough and can sustain temperatures up to 1000 degrees.

Ceramics

The most popular ceramic materials are aluminum oxide and silicon nitride. They are strong in compression. Ceramics can hold up to a temperature of 1800 degrees celsius. The friction between the tool face and the chip is very low and also the heat conductivity is low, no coolant is normally required. They create a fantastic surface finish.

Cubic boron nitride tool (CBN)

After diamonds, cubic boron nitride is the second hardest material. They're commonly seen in hand machinery. CBN has high abrasion resistance and is used as abrasives in grinding wheels.

Diamond tool

Diamond tools are the hardest and most valuable material known to man. They have a high melting point and thermal conductivity. Diamond tools are great for surface polish and dimensional accuracy.

Maintenance and Care for Round Paper Cutting Blade

Proper maintenance and care of Round Paper Cutting Blade are crucial for their performance and longevity. Here are simple yet effective ways to keep your Round Paper Cutting Blade in top-notch condition:

Cleaning

Always start with cleaning your tools after use. Dirt, debris, or any material remnants can affect the tool's efficiency and lead to premature wear. Use a soft brush or cloth to remove particles. For stubborn residues, a mild solvent may be necessary. A clean tool is a happy tool.

Sharpening

Dull tools not only work poorly but also pose a safety risk. Regular sharpening ensures your Round Paper Cutting Blade cut efficiently and accurately. However, it's important to follow the manufacturer's guidelines for sharpening to avoid damaging the tool. If you're unsure, consider professional sharpening services.

Storage

Proper storage is key to protecting your tools from damage and environmental conditions. Keep them in a dry, clean place to prevent rust and corrosion. For precision tools, consider using protective covers or cases to shield them from accidental drops or impacts.

Inspection

Regular inspection can catch issues before they become serious problems. Look for signs of wear, damage, or alignment issues. Early detection means you can repair or replace a tool before it fails during a critical job.

Lubrication

Lubrication reduces friction, helping your tools to operate smoothly and extending their lifespan. Use the appropriate lubricant for your tool type and application. Some tools may require specific lubricants to function correctly, so always check the manufacturer's recommendations.

- When the round paper cutting blade is not in use, the blade should be hung vertically on a dry shelf, and the round paper cutting blade should not be placed flat.

- The teeth of the round paper cutting blade are super hard and sharp, so it is forbidden to collide and fall on the ground, and must be taken lightly.

- Operation must be with protective shield, work gloves, safety helmet, safety shoes, protective glasses.

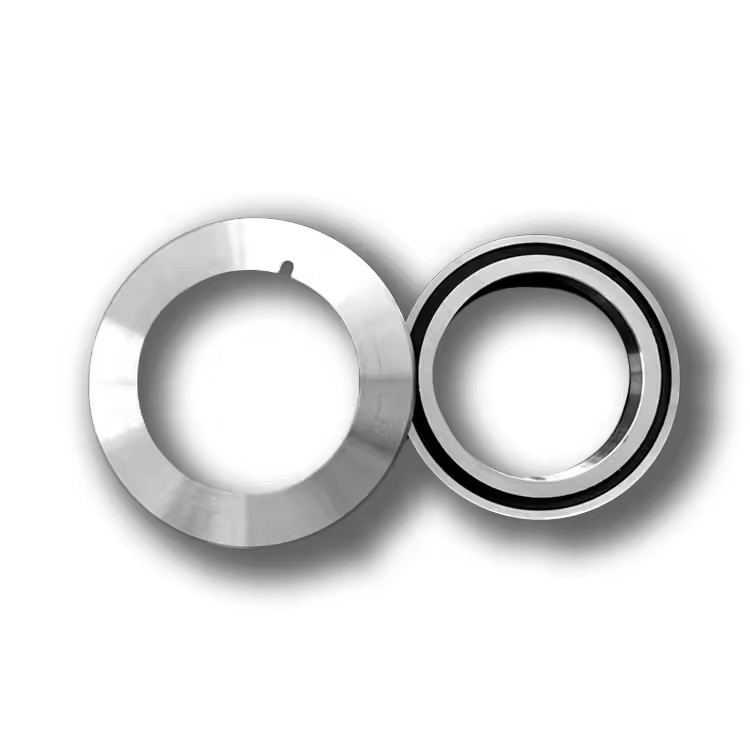

- In the installation of the round paper cutting blade before, must first confirm the performance of the saw table, use, to ensure that the round paper cutting blade arrow indicates the cutting direction and the direction of rotation of the saw table consistent. Installation in the opposite direction is strictly prohibited, the wrong direction may cause the blade teeth to fall off to prevent accidents.

- When installing the round paper cutting blade, must first check whether the round paper cutting blade has a crack, distortion, flattening, falling teeth and other phenomena, and then install.

- After installation, need to confirm whether the center hole of the round paper cutting blade is firmly fixed on the flange of the saw table, and the gasket must be set when there is a gasket; then, gently push by hand to confirm whether the round paper cutting blade rotation is eccentric shaking.

- When using, please do not exceed the maximum speed specified.

- Pre-rotation before use: After replacing the new blade, you need to pre-rotate for one minute before use, so that the saw table into working condition, before cutting.

- The hardness requirements of the round paper cutting blade is very important, sometimes your material and then good hardness requirements are not reasonable blade will appear chipped.

How to Install The Round Paper Cutting Blade

Install the blade

Before using the round paper cutter, you need to install the blade first. First, remove the handle of the paper cutter, place the blade in the handle base, then press the handle with your fingers, and merge the handle and base while ensuring that the blade is firmly fixed.

Adjust the cutting depth

In order to obtain the best cutting effect and avoid damaging the work surface or cutting to the bottom under the table, you need to adjust the cutting depth of the round paper cutter appropriately. The adjustment method is as follows:

- Loosen the fixing nut and point the cutting depth scale on the base toward the top of the material to be cut;

- Rotate the blade base and gradually lower the blade depth to the appropriate height. The initial depth should be lightly touching the surface of the material;

- Point the cutting depth scale on the base to the desired cutting depth and re-tighten the nut.

Our Factory

Ganzhou Big Brother Cutting Tools Co., Ltd. is a professional manufacturer and processor of industrial cutting tools. The company team has 15 years of industry experience and has successfully completed technological transformation through years of continuous accumulation and exploration.Also skilled in researching and producing non-standard cutting tools, molds, etc The main products include: packaging machine knives, non-standard blades, industrial knives, food machine knives, woodworking planers, alloy blades, precision knife molds, shredder knives, agricultural machinery knives, and various mechanical cutting tools for mass production and non-standard customization.

FAQ

Q: What is a round paper cutting blade used for?

Q: What materials are round paper cutting blades typically made of?

Q: How does the diameter of a round paper cutting blade affect its performance?

Q: What are the safety precautions to consider when handling round paper cutting blades?

Q: Can round paper cutting blades be sharpened, or do they need to be replaced?

Q: What are the common types of round paper cutting blades?

Q: How often should round paper cutting blades be replaced?

Q: What is the proper way to clean a round paper cutting blade?

Q: Are there any specific maintenance tips for round paper cutting blades?

Q: Where can I find high-quality round paper cutting blades?

Q: What is a round blade?

Q: What is the use of paper cutter blade?

Q: Which blade is best for cutting?

Q: What size are paper cutter blades?

Q: What type of saw has a round cutting blade?

Q: What are circular blades used for?

Q: What are the three types of paper cutter?

Q: Is paper trimmer same as paper cutter?

Q: What are cutting blades used for?

Q: Which blade type is best?