Description

Rubber cutting blades are an essential tool for many industries that work with rubber materials. These blades are designed to cut through rubber with ease and precision, allowing for accurate cuts that ensure the material is properly sized for its intended use. With the right rubber cutting blade, workers can significantly improve their efficiency and accuracy in their work.

Advantages of Rubber Cutting Blade

Durability

Rubber cutting blades are made of high-quality materials resistant to wear and tear, meaning they can last for a long time with proper maintenance and handling.

Versatility

Rubber cutting blades can be used to cut a wide range of rubber materials, including natural rubber, synthetic rubber, and silicone, making them versatile tools for various cutting applications.

Customization

Rubber-cutting blades are highly customizable to meet the specific needs of different rubber-cutting applications, such as cutting, scoring, perforating, and more.

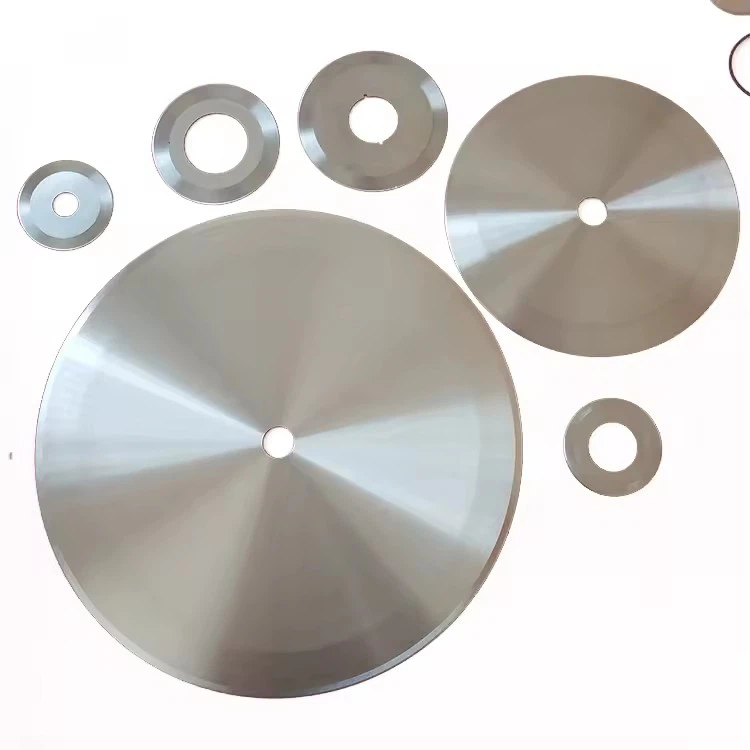

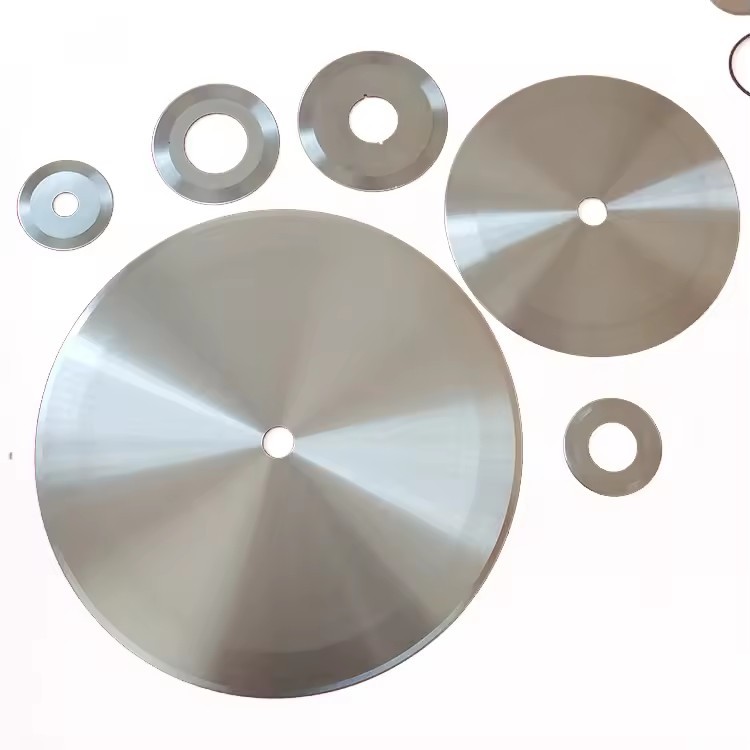

Round Packaging Machinery Blade

Round packaging machinery blade is an essential tool used in the packaging industry. It is responsible for ensuring that products are properly packaged and prepared for shipping. This blade is designed to be durable and efficient, allowing businesses to cut down on their production time and increase their output.

Round paper cutting blade is a useful tool that can make precise cuts on paper with ease. It is a perfect tool for those who work with paper on a regular basis or those who enjoy paper crafting as a hobby.

Circular Slitter Blades Applicable industries: Hotels, clothing stores, building materials stores, manufacturing factories, machinery maintenance stores, food and beverage factories, farms, household use, retail, food stores, printing stores, construction engineering, energy and mining, food and beverage stores, advertising companies.

Why Choose Us

Factory

company team has 15 years of industry experience. Through years of continuous accumulation and exploration, it has successfully completed technological transformation.

High-quality service

We insist on returning the support and love of our customers and friends from all parties with stable, reliable, economical, durable and high-quality products.

Customized service

Our team of experts will work closely with you to understand your needs and provide tailor-made solutions to meet your expectations.

Competitive price

We are confident in the quality of our products and are willing to provide you with long-term technical service support.

Types of Rubber Cutting Blade

Serrated blade

Serrated blade is one of the most common blades used for cutting rubber materials. It is sharp and efficient, and can complete the cutting operation in a short time. When used in car rubber, serrated blades can easily cut rubber materials and are suitable for situations where the rubber hardness is high. However, it should be noted that when using serrated blades, it is necessary to frequently clean the rubber fragments on the blade, otherwise it will affect the cutting effect.

Flat blade

The advantage of flat blade is that the cutting edge is neat, without serrations and burrs, and it is suitable for situations where the rubber hardness is low and the viscosity is strong. In addition, the service life of flat blades is relatively long, and it can be reused many times to reduce the cost of use.

Smooth blade

Smooth blades are also commonly used for cutting car rubber. They are characterized by smooth surface and will not damage the rubber surface during cutting. They are suitable for occasions where the integrity of the rubber surface needs to be protected. When using smooth blades, you need to pay attention to the cutting speed. Cutting too fast will cause the surface of the cut to melt and deform.

Application of Rubber Cutting Blade

Cutting rubber tubes

Rubber tubes are one of the key components of many mechanical equipment. They are used to transport liquids or gases. However, the length and diameter of rubber tubes may not meet the requirements of the equipment and need to be cut. Rubber cutters can accurately cut rubber tubes into the required length and diameter to meet the requirements of different equipment.

Cutting rubber sheets

Rubber sheets are suitable for making many industrial products, such as rubber sealing sheets, rubber coated sheets, etc. However, the size and shape of rubber sheets are not fixed and need to be cut according to requirements. Rubber cutters can quickly and accurately cut rubber sheets into the required size and shape to improve production efficiency.

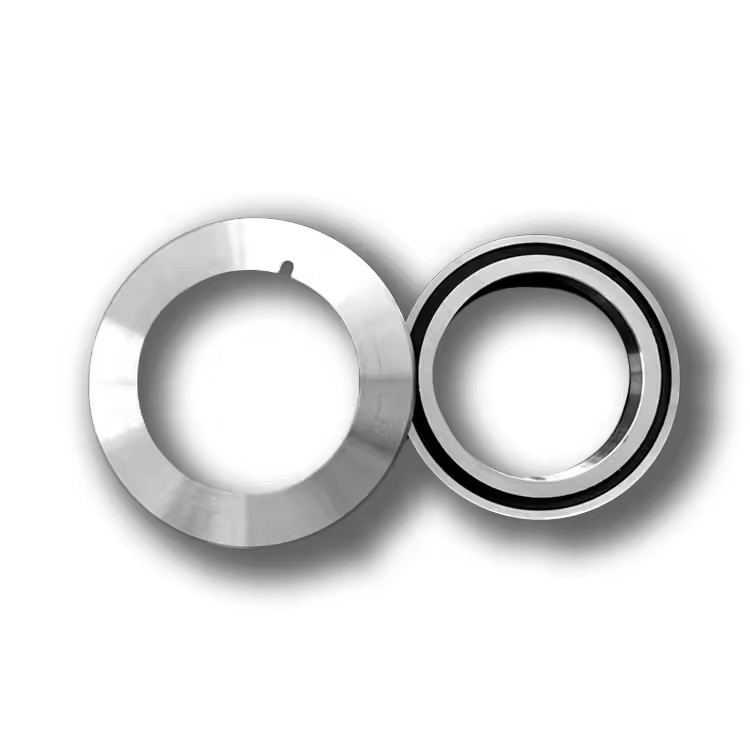

Cutting rubber sealing rings

Rubber sealing rings are an indispensable part of many equipment. However, the size, shape, thickness and other parameters of rubber sealing rings are not the same and need to be cut. Rubber cutters can cut rubber sealing rings into various specifications to meet the requirements of various equipment.

Components of Rubber Cutting Blade

Diamonds

The predominant constituent of a diamond saw blade is, naturally, the diamonds themselves. Diamonds serve as the active cutting agents, necessitating the selection of blades featuring high-quality, industrial-grade diamonds. Typically, diamonds are embedded within the segments or ridges of the blade, or form a continuous rim encircling the blade's circumference.

Metal core

The metal core serves as the backbone of the blade, furnishing stability and support for the diamonds. Usually crafted from high-quality steel or another metal engineered to withstand cutting stresses, the thickness and strength of the metal core vary based on blade type and the materials designated for cutting.

Segments or ridges

Segments or ridges are the raised portions of the blade containing the embedded diamonds. These components are engineered to deliver aggressive cutting action while securing the diamonds in place during cutting. The number, size, and arrangement of segments or ridges vary according to blade type and the materials targeted for cutting.

Continuous rim

A feature found in certain types of diamond blades, such as continuous rim blades, is the continuous rim itself. Housing a continuous row of diamonds, this design ensures a smooth and precise cut. The size and arrangement of diamonds within the continuous rim are contingent upon blade type and the materials slated for cutting.

Cooling system

During cutting, diamond blades generate substantial heat, which may accelerate blade wear and diminish diamond cutting effectiveness. To mitigate this issue, many diamond blades incorporate a cooling system, such as water channels or air vents, to regulate blade temperature during operation.

Flange

The flange represents the component of the blade that affixes it to the cutting machine, such as a saw or grinder. Designed to securely fit the machine and furnish stability and support during cutting, flange size and shape vary depending on blade type and the cutting machine for which it is intended.

Material of Rubber Cutting Blade

Carbon tool steel

Carbon steel is used for low-speed machining operations. Abrasion resistance and the ability to keep a sharp cutting edge are two advantages of high carbon steels. Carbon tool steels have high machinability. Carbon steel starts melting at a temperature of approx. 180 – 250 degrees. As a result, it is unable to operate at high temperatures.

High-speed steel (HSS)

High-speed steel is widely used in machining operations. HSS tools are used to make complex-shaped tools like drills, reamers, taps, dies, and gear cutters. They are robust and ideal for interrupted cutting. HSS loses its hardness at a temperature of approx. 600-650 degrees. As a result, a coolant should be applied to extend the tool's life. It can be re-sharpened and used multiple times.

Cemented carbide

Cemented carbide cutting tool consists of tantalum, tungsten, and titanium carbide with cobalt as a binder. Carbide tools are extremely tough and can sustain temperatures up to 1000 degrees.

Ceramics

The most popular ceramic materials are aluminum oxide and silicon nitride. They are strong in compression. Ceramics can hold up to a temperature of 1800 degrees celsius. The friction between the tool face and the chip is very low and also the heat conductivity is low, no coolant is normally required. They create a fantastic surface finish.

Cubic boron nitride tool (CBN)

After diamonds, cubic boron nitride is the second hardest material. They're commonly seen in hand machinery. CBN has high abrasion resistance and is used as abrasives in grinding wheels.

Diamond tool

Diamond tools are the hardest and most valuable material known to man. They have a high melting point and thermal conductivity. Diamond tools are great for surface polish and dimensional accuracy.

Maintenance and Care for Rubber Cutting Blade

Cleaning

Always start with cleaning your tools after use. Dirt, debris, or any material remnants can affect the tool's efficiency and lead to premature wear. Use a soft brush or cloth to remove particles. For stubborn residues, a mild solvent may be necessary. A clean tool is a happy tool.

Sharpening

Dull tools not only work poorly but also pose a safety risk. Regular sharpening ensures your rubber cutting blade cut efficiently and accurately. However, it's important to follow the manufacturer's guidelines for sharpening to avoid damaging the tool. If you're unsure, consider professional sharpening services.

Storage

Proper storage is key to protecting your tools from damage and environmental conditions. Keep them in a dry, clean place to prevent rust and corrosion. For precision tools, consider using protective covers or cases to shield them from accidental drops or impacts.

Inspection

Regular inspection can catch issues before they become serious problems. Look for signs of wear, damage, or alignment issues. Early detection means you can repair or replace a tool before it fails during a critical job.

Lubrication

Lubrication reduces friction, helping your tools to operate smoothly and extending their lifespan. Use the appropriate lubricant for your tool type and application. Some tools may require specific lubricants to function correctly, so always check the manufacturer's recommendations.

By incorporating these maintenance practices into your routine, you can ensure your rubber cutting blade remain in prime condition, ready for whatever job comes next. This not only maximizes the tool's lifespan but also enhances safety and efficiency in your projects.

How Are Rubber Cutting Blades Made

Material selection

Tool Steel: High-speed tool steel (HSS) or tungsten carbide are commonly used cutting tool materials due to their hardness, wear resistance, and heat resistance.

Ceramics: Some cutting tools are made of ceramics, which have high-temperature resistance and are suitable for specific machining applications.

Carbide Inserts: Carbide inserts are commonly used in milling, turning, and drilling tools. They consist of a carbide core and are mounted on a tool holder.

Design and engineering

Cutting tools are designed using computer-aided design (CAD) software to create precise geometry and cutting edge profiles.

Engineers consider factors such as tool geometry, rake angle, relief angle, and chip evacuation when designing rubber cutting blades.

Manufacturing process

Blanking: The initial shape of the rubber cutting blade is cut or stamped from a larger piece of tool steel or carbide.

Heat Treatment: The blank undergoes a heat treatment process to achieve the desired hardness and toughness. This involves heating and quenching to precise temperatures.

Grinding: The cutting edge and surface are ground to achieve the necessary sharpness and precision.

Coating: Many rubber cutting blades are coated with a thin coating of carbide, ceramic or other materials to enhance wear resistance and reduce friction.

Edge preparation: The cutting edge is honed and finished to ensure sharpness and consistency.

Quality control

Strict quality control measures are taken throughout the manufacturing process to ensure that the cutting tools meet specific dimensional and performance standards.

Tools are inspected for hardness, sharpness and overall quality.

Customization

Rubber cutting blades can be customized for specific applications. For example, different coatings or geometries can be used to cut different materials (such as aluminum, steel or composites).

Blades and tool holders can be customized for different processing systems and machines.

Packaging and distribution

Once manufactured and quality-checked, the cutting tools are packaged and distributed to manufacturers, machine shops and other end users.

Rubber cutting blades play a vital role in precision machining and manufacturing, and their quality and durability are essential to obtain a high-quality finished product. The materials, design and manufacturing processes used ensure that rubber cutting blades can meet the needs of a variety of machining applications.

Process of Rubber Cutting Blade

Cutting

The first step in making these blades is to cut a metal sheet into the appropriate shape. A CNC machine is usually used for this technique.

01

Heating

The blade is next subjected to a procedure known as heat treatment, which involves quickly cooling after heating to a very high temperature in order to harden and strengthen the steel.

Brazing is an optional method for joining tiny metal bits to circular, toothed blades.

02

Sharpening

The blade needs to be honed to get rid of any flaws after it has reached the correct shape. further to produce the bevel, the sharp edge of the blade. Ultimately, the edge of the blade is sharpened even further by grinding.

03

Coating

To aid increase resistance to wear and corrosion, the blade tips can also be coated with various materials.

04

How to Choose a Rubber Cutting Blade

Commonly used rubber cutter size specifications

The size specifications of rubber cutters are usually divided into three dimensions: Length, width, and thickness. Commonly used size specifications include 10cm, 15cm, 20cm, 25cm and other specifications to choose from.

Choose the right size

Common rubber cutting needs include customizing rubber sealing strips, cutting rubber sheets, etc. For the needs of customizing rubber sealing strips, generally choose a smaller rubber cutter size, which is light and flexible; for the needs of cutting rubber sheets, generally choose a larger rubber cutter size, which can better adapt to the cutting of large-sized rubber materials.

The impact of size on rubber cutting effect

The size of the rubber cutter has a great impact on the rubber cutting effect. Smaller rubber cutter sizes can better cut small objects, but the corresponding cutting speed will be slower; larger rubber cutter sizes can cut large-sized objects faster, but the precision will be low when cutting small objects.

Precautions

When purchasing a rubber cutter, you need to choose a reliable brand and manufacturer to ensure the quality and safety of the product.You need to master the correct operation method when using it to avoid damage to people or objects due to improper operation.Pay attention to safety when using the rubber cutter to avoid cutting your fingers or other important parts.

Our Factory

Ganzhou Big Brother Cutting Tools Co., Ltd. is a professional manufacturer and processor of industrial cutting tools. The company team has 15 years of industry experience and has successfully completed technological transformation through years of continuous accumulation and exploration.Also skilled in researching and producing non-standard cutting tools, molds, etc The main products include: packaging machine knives, non-standard blades, industrial knives, food machine knives, woodworking planers, alloy blades, precision knife molds, shredder knives, agricultural machinery knives, and various mechanical cutting tools for mass production and non-standard customization.

FAQ

Q: What blade cuts rubber?

Q: What are cutting blades used for?

Q: What can cut through rubber?

Q: Which blade is best for cutting?

Q: Can I cut rubber with a circular saw?

Q: Which method of cutting is used to cut rubber?

Q: What material is used for cutting blades?

Q: What is the purpose of blade?

Q: What were blades used for?

Q: Can you cut rubber with a knife?

Q: Can I cut rubber with a table saw?

Q: How do I choose a blade?

Q: Which blade type is best?

Q: What are the sharpest cutting blades?

Q: What is the best tool to cut rubber?

Q: What saw is best for cutting rubber?

Q: What cuts rubber mats?

Q: Where can I cut rubber?

Q: What is rubber cutting machine?

Q: What is the best blade for cutting?