Description

Product Introduction

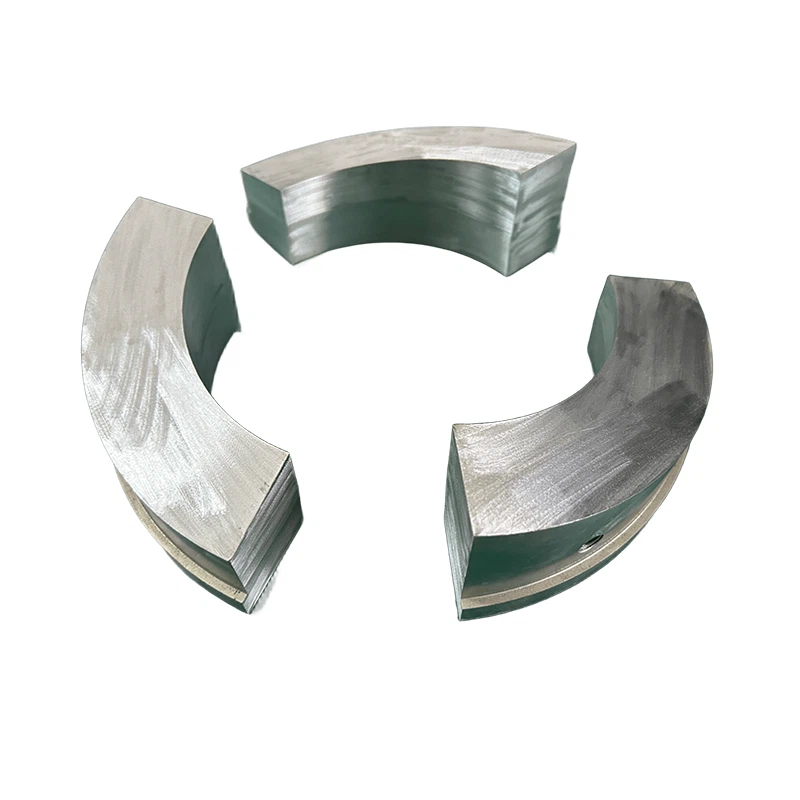

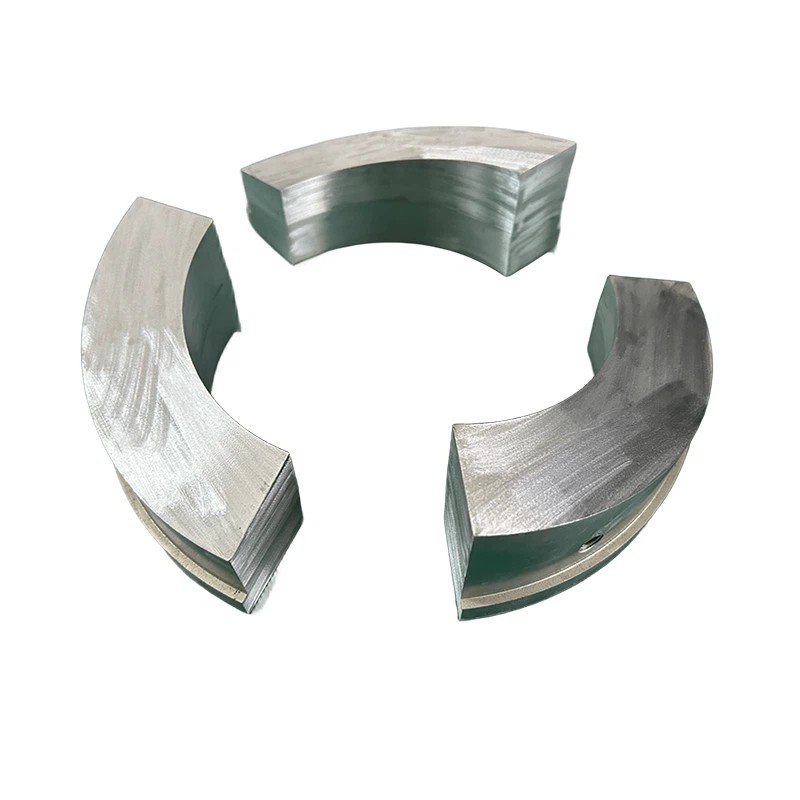

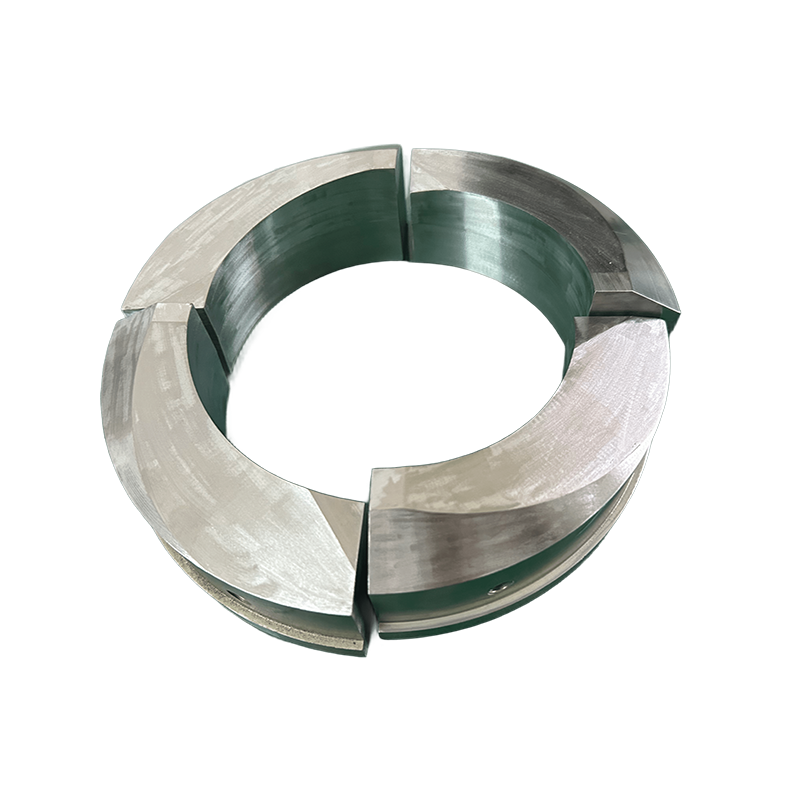

1. Shape:

The Shield Machine Blade is circular, with a large hole in the center, and cutting edges on both the outer and inner rings.

2. Material:

The cutter head is mainly made of hard alloy composed of high-strength tungsten and cobalt elements, capable of withstanding high pressure and strong wear in complex geological conditions.

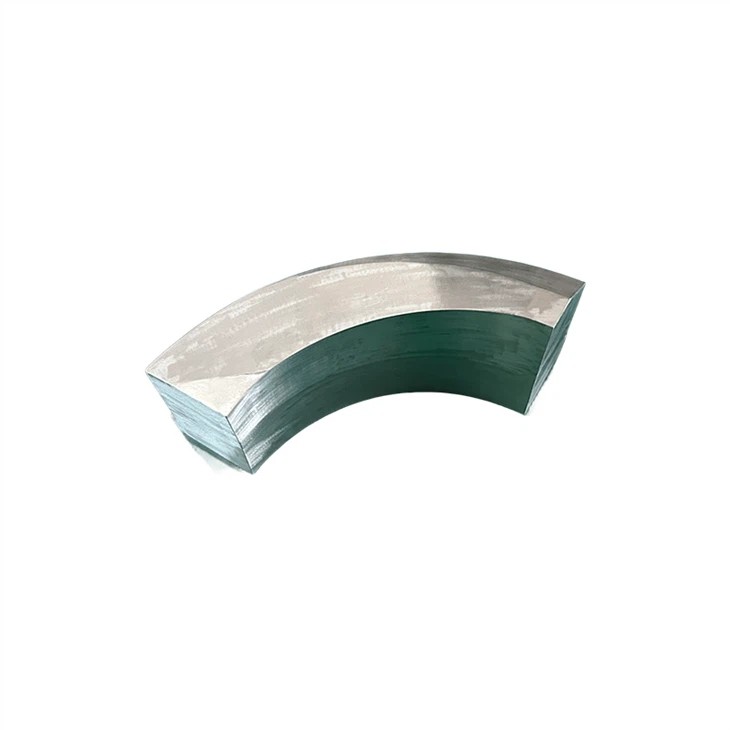

3. Structure:

The blade is made up of multiple segments, each with sharp edges used for cutting and crushing soil or other materials.

4. Application:

The cutter head of a tunnel boring machine is a crucial component in the excavation of underground tunnels. The Shield Machine Blade on the cutter head are responsible for cutting and breaking through the soil or rock ahead to advance the tunnel.

Product Features

01 Waterproof

The surface of the shield machine blade is coated with a 50-100 nanometer thick diamond-like carbon (DLC) protective film by physical vapor deposition (PVD) technology, with a contact angle greater than 110° that makes it difficult for water droplets to adhere to its surface, effectively preventing moisture penetration and strong waterproofness.

02 High Strength

The Shield Machine Blade is made of high-strength alloy steel with a yield strength of more than 1200MPa and a tensile strength of more than 1500MPa. Facing hard rock layers, it can easily exert huge cutting forces and is not easy to bend or break. Ensure construction efficiency and safety.

03 High Precision

The shield machine blade uses five-axis linkage processing technology, and the blade size accuracy is controlled within ±0.01mm.This high-precision machining process ensures that the cutting disc aligns perfectly with other components of the tunnel boring machine, enhancing overall mechanical performance and reducing wear, while also ensuring accuracy and stability during tunnel excavation.

04 Durable

The cutting wheel is made of high-quality stainless steel and other materials, which provide wear resistance and corrosion resistance, thereby extending its lifespan and reducing maintenance costs.

Working process

wide application of technology

As the tunnel boring machine advances, its cutting wheel rotates with the cutter head. The rotation speed and torque of the cutting wheel can be precisely adjusted through the control system to ensure efficient excavation and protect the equipment.

in soft soil formations

The scraper, designed with sharp edges and specific angles, effectively removes soil. It utilizes the rotational force of the cutting machine and the thrust of the shield machine to scrape away soft soil, much like a knife cuts through an object.

In hard rock formations

The roller cutter, made from wear-resistant materials and capable of withstanding high pressure and friction, crushes rock as it presses against it. The rock breaks under the combined forces of compression and shearing generated by the roller's rotation.

Send out

Since the rotary cutter is made from wear-resistant materials and can withstand high pressure and friction, it crushes the rock pushed by the cutting machine under the compressive and shearing forces generated by its rotation.

Blade Replacement Procedure

![]()

First, the shield machine stops excavation and performs soil discharge and pressure reduction operations in the soil bin.

![]()

Then, the staff enters the soil bin, removes the fixing bolts and other connectors of the worn blade, and takes out the old blade.

![]()

Next, hoist the new shield machine blade to the installation location, tighten the fixing bolts according to the specified torque, and ensure that it is firmly installed.

![]()

Finally, check the newly installed blade and resume excavation after it is correct.

Key Maintenance Points

1

Regularly check

Regularly inspect the wear condition of the TBM cutting tools, including the degree of wear on the cutting edges and the tightness of the fixing bolts. The wear of the cutting edges directly affects the excavation efficiency and construction quality, so they need to be replaced or repaired promptly. The tightness of the fixing bolts is related to the stability and safety of the cutting tools, and it must be ensured that they are securely fastened.

2

Keep clean

3

Maintain lubrication system

Safety precautions

environmental safety

Before entering the soil chamber, use an oxygen detector and flammable gas detector for professional gas testing. Ensure that any potential hazardous gases are removed through mechanical ventilation or natural ventilation. It is essential to guarantee the safety of the gases within the soil chamber.

personnel safety

Workers should wear safety helmets, safety ropes, and other protective gear. When removing and installing shield machine blades, precautions must be taken to prevent the blades from falling and injuring people. When removing the blades, specialized shield machine blade tools should be used. When installing the blades, ensure they are securely fixed to avoid accidents caused by loosening.

FAQ

01. Q: Do you provide samples? Are they free or do they come at an additional cost?

A: Yes, we can offer the sample free of charge, but you will need to cover the cost of freight.

02. Q: Is it possible to print my logo on the blade or customize my own packaging?

03. Q: What are your terms of payment?