Description

Blades designed to cut through tire rubber are called tire-cutting blades. They are used to cut old tires into smaller pieces for recycling or disposal in a variety of industries, including trucking, the automotive industry, and waste management.Due to the rough and abrasive nature of cutting through composite materials, tire-cutting blades must be durable and wear-resistant.

Advantages of Tire Trimming Blade

Efficiency

Industrial tire-cutting blades are designed to cut through tough rubber and other materials quickly and efficiently, reducing the time and labor needed to complete a task.

Safety

Tire-cutting blades can reduce costs in the long run by reducing waste and increasing efficiency.

Durability

Industrial tire-cutting blades are made from high-quality materials built to last, meaning they can withstand the rigors of heavy use without wearing out or breaking.

Easy maintenance

Industrial tire-cutting blades are typically easy to maintain, requiring minimal cleaning and upkeep to keep them in good working condition.

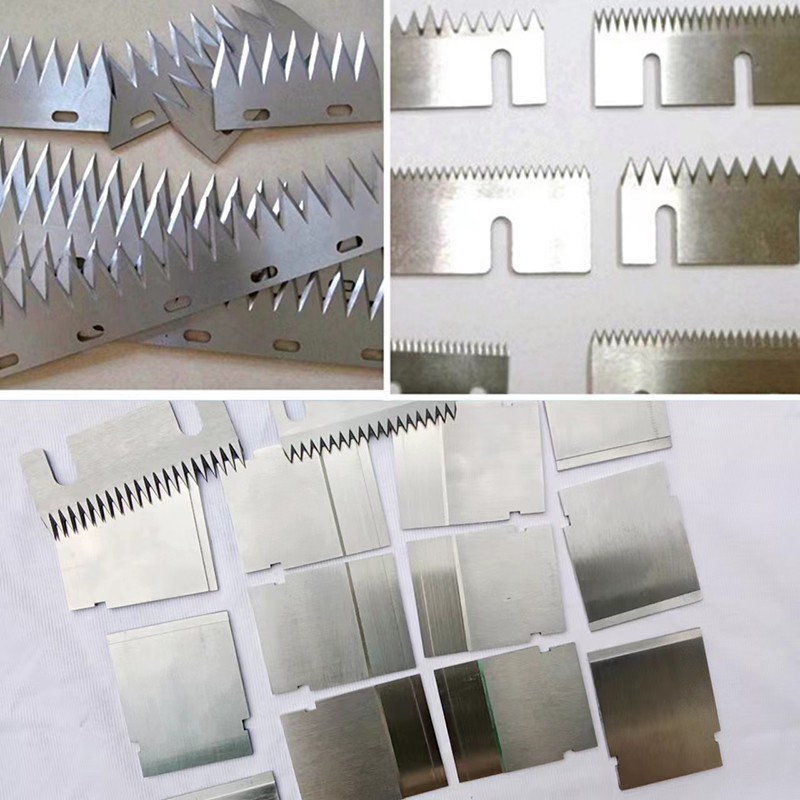

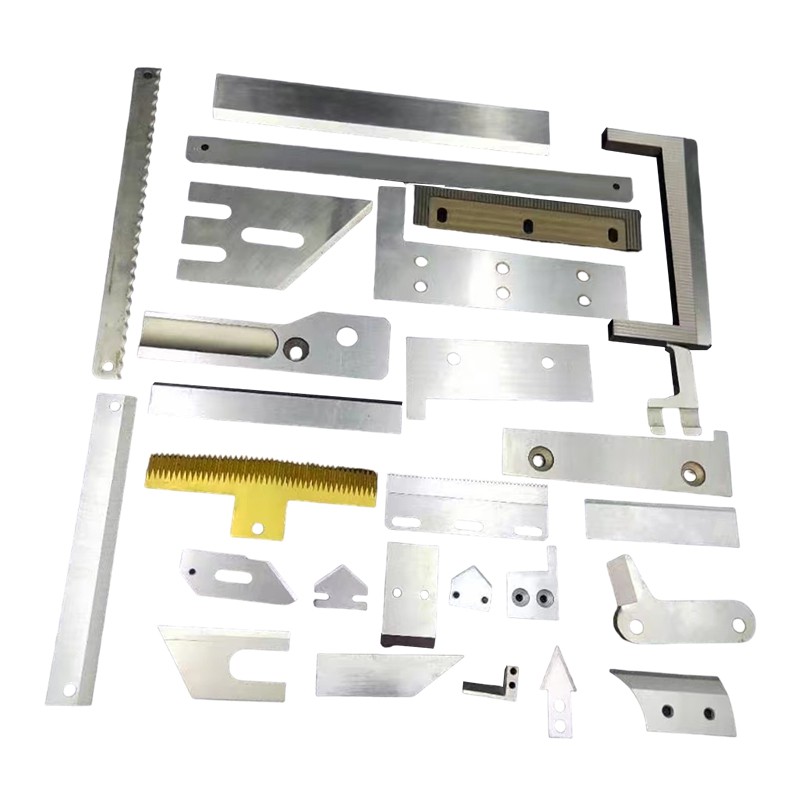

Toothed blade is a cutting tool commonly used in mechanical processing and medical treatment.This type of blade has advantages such as high durability, high precision, and high efficiency, and can quickly complete cutting work during the machining process, providing necessary assistance for the production process.

The sealing machine blade is a key component widely used in the packaging field. It is made of high-quality steel and has excellent wear resistance, corrosion resistance, and cutting performance. The sealing machine blade not only can easily cut various packaging materials, such as cartons, foam boards and plastic sheets, but also can be switched and adjusted according to different needs, with high flexibility.

Charter machine blade is a common metal cutting tool, mainly used for cutting and cutting materials in the feeding machine equipment. This type of blade has a simple structure, is easy to install and replace, greatly improving cutting efficiency and accuracy.

Jelly machine blades are indispensable cutting tools on jelly production lines. They are made of high-strength stainless steel, with a beautiful appearance and reliable quality. The design of the blade is flexible and can be adjusted according to the hardness and shape of different jellies, ensuring that each piece of jelly can be cut evenly and neatly.

Automatic packaging blades are state-of-the-art cutting tools that play a pivotal role in the packaging industry. These blades are designed to provide efficient and accurate results, while also reducing the risk of errors and injuries. They are specifically designed to cut through a wide range of packaging materials including tapes, films, foils, and papers.

Non-standard blades refer to blades that are specifically designed and manufactured for a particular use, rather than being standard, off-the-shelf items. These blades are tailor-made to suit the specific needs of a particular application. They are used in various industries such as aerospace, automotive, medical, and manufacturing.

Dotted paper cutting blade is a cutting tool suitable for cutting items such as dot matrix paper, greeting cards, envelopes, etc. Its blade is designed with many small serrated blades, which can cut high-quality lattice lines in a short time, making the cutting effect more beautiful.

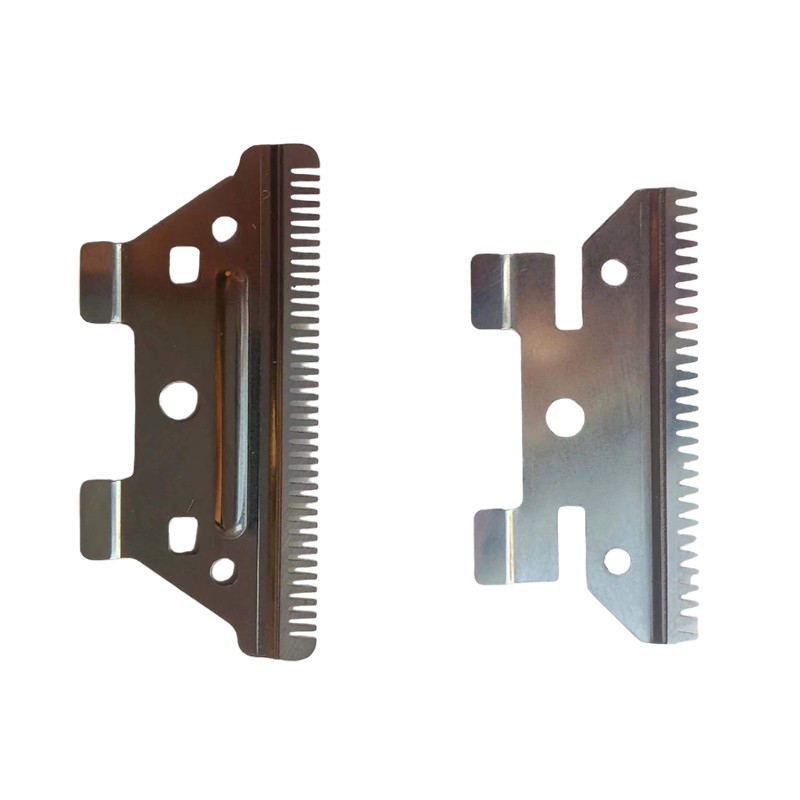

Filling Machine Tooth Cutting Blade

Filling machine tool cutting blade is a cutting blade used for filling machines. It is widely used in the production process of industries such as food, medicine, cosmetics, etc., to cut materials and complete the sealing of bottles or bags. Its design ensures precise cutting and sealing during the filling process, ensuring product quality and hygiene standards.

Packaging machine blades are widely used in the process flow of various sewage treatment plants to promote the mixing of wastewater containing suspended solids, diluted mud, industrial process liquids, etc.

Why Choose Us

Factory

The company is a professional industrial cutting tool production and processing enterprise. The company team has 15 years of industry experience. Through years of continuous accumulation and exploration, it has successfully completed technological transformation.

High-quality service

We insist on returning the support and love of our customers and friends from all parties with stable, reliable, economical, durable and high-quality products.

Customized service

Our team of experts will work closely with you to understand your needs and provide tailor-made solutions to meet your expectations.

Competitive price

We are confident in the quality of our products and are willing to provide you with long-term technical service support.

Types of Tire Trimming Blade

Cutter

Cutter is one of the more commonly used tools for repairing tire rubber burrs. It is mainly used to cut the burrs of tires and trim the boundary lines. The sharp blade can penetrate the tire rubber material well without too much effort. When using a cutter, be careful that the blade is very sharp. In order to prevent the blade from becoming blunt, it is best to prepare multiple blades to use in turn, and pay attention to safety during use.

Herringbone knife

When the herringbone knife is used to repair the burrs, the contact surface between the tire burrs and the tire can be made smoother, which can improve the stability and grip of the tire. The herringbone knife is also one of the common tools for repairing tire burrs. Its blade is in the shape of a herringbone, which is very suitable for cutting in curved areas. When using a herringbone knife, be careful not to use too much force to avoid damage to the blade.

Shovel

The scraper is a tool with relatively good cutting performance, which can well fill the burrs and bubbles of rubber products such as tires. The scraper is generally designed in an L-shaped or T-shaped design, which is conducive to operation and uniform force. When using a scraper, be careful that the scraper is harder, and it is best to use a protective glove to avoid tilting the blade and damaging the tire rubber burrs.

Material of Tire Trimming Blade

Ceramic alumina

Ceramic alumina may be a self-sharpening and funky cutting grain that cuts at lower temperatures and with less friction, reducing heat discoloration of the workpiece. Ceramic grains utilize a crystalline structure designed with many fracture points that self-sharpen at a better rate than other grains. The results a better material removal rate, faster-cutting speeds, cooler grinding, and reduced friction at less pressure, reducing operator fatigue.

Zirconia alumina

Zirconia alumina has self-sharpening crystals, the delay under extreme pressure. Zirconia alumina retains a high cut-rate throughout the life of the wheel, delivering exceptional performance.

Aluminum oxide

Aluminum oxide may be a single crystal that gives an initial harp cut.

Silicon carbide

Silicon carbide is an incredibly hard grain that's very sharp and fast cutting. It's also friable in comparison to other grains.

How to Maintain Tire Trimming Blade

Check before use

Before use, check whether the blade is damaged or deformed, and confirm whether the blade has cracks and whether the sharpness meets the processing requirements. If any problems are found, they should be replaced or adjusted in time.

Precautions during use

Before processing, the tire needs to be evenly placed on the cutting table to avoid dislocation and deflection.

During the processing, the contact area between the blade and the tire should be sufficient, the cutting speed should be uniform, and try to avoid short stops during cutting.

Clean the blade regularly to ensure that the surface is clean. Do not let the blade surface be stained with oil, dust and other substances to avoid affecting the cutting quality.

Storage and maintenance

After use, the blade surface should be cleaned immediately and maintenance oil should be applied to prevent rust.

For blades that are not used for a long time, they need to be packaged and stored in a dry, ventilated, light-proof and corrosion-resistant environment.

Process of Tire Trimming Blade

![]()

Cutting

The first step in the manufacturing process is to use a CNC machine to cut the blade to the desired shape.

![]()

Heating

Next, the blade is put through a heat treatment process to harden the metal and makes it more durable.

![]()

Sharpening

After heating, the blade is sharpened to remove any imperfections. A grinding process is then used to refine and make the blade sharper.

![]()

Coating

By coating the tips of blades with these metals, the blade can better withstand wear and tear. It can prolong the blade's lifespan.

Maintenance and Care for Tire trimming blades

Cleaning

Always start with cleaning your tools after use. Dirt, debris, or any material remnants can affect the tool's efficiency and lead to premature wear. Use a soft brush or cloth to remove particles. For stubborn residues, a mild solvent may be necessary. A clean tool is a happy tool.

Sharpening

Dull tools not only work poorly but also pose a safety risk. Regular sharpening ensures your Tire trimming blades cut efficiently and accurately. However, it's important to follow the manufacturer's guidelines for sharpening to avoid damaging the tool. If you're unsure, consider professional sharpening services.

Storage

Proper storage is key to protecting your tools from damage and environmental conditions. Keep them in a dry, clean place to prevent rust and corrosion. For precision tools, consider using protective covers or cases to shield them from accidental drops or impacts.

Inspection

Regular inspection can catch issues before they become serious problems. Look for signs of wear, damage, or alignment issues. Early detection means you can repair or replace a tool before it fails during a critical job.

Lubrication

Lubrication reduces friction, helping your tools to operate smoothly and extending their lifespan. Use the appropriate lubricant for your tool type and application. Some tools may require specific lubricants to function correctly, so always check the manufacturer's recommendations.

How to Choose a Tire Trimming Blade

Material selection

The material of the Tire trimming blades blade should be selected with high hardness, strong wear resistance and corrosion resistance, usually high-quality alloy tool steel or tungsten carbide steel.

Shape selection

The shapes of the Tire trimming blades blade include straight blade, wave shape, sawtooth shape, etc., and the appropriate shape needs to be selected according to the specific occasion. Generally speaking, the straight blade type is suitable for simple tire processing, the wave shape is suitable for peripheral cutting, wire cutting and other processing, and the sawtooth shape is suitable for processing complex curves such as tire corners.

Hardness selection

The hardness selection of the Tire trimming blades blade needs to be determined according to the hardness, thickness and processing requirements of the cutting material. Too low hardness will cause serious blade loss, and too high hardness will increase the brittleness of the blade and make it easy to break.

Safety Precautions When Using the Tire Trimming Blade

You should only use the right tool for the job at hand. Never use a tire trimming blade for a purpose or function that it was not designed for. When you use any equipment for purposes other than those for which it was intended, the tool may react unexpectedly, potentially causing injury.

Make sure all employees who use tire trimming blades are adequately trained in their use. Many unnecessary injuries occur simply because someone was not properly trained in their use.

Check your tire trimming blades regularly. A dull or damaged blade requires more mechanical force to be effective. Blade failure can damage the equipment, or even worse, the person operating that equipment.

If possible, make sure you are working in an environment with proper visibility. Some work environments prevent this from happening, but every effort should be made to maximize visibility.

If there is a chance that you could accidentally come into contact with a tire trimming blade, you should always wear appropriate personal protective equipment (PPE), such as cut-resistant gloves, as well as safety glasses to protect your eyes in the event of a blade failure.

When the blade you are using is manually operated, you should always cut away from yourself and make sure no part of your body is in the path of the cut. Also be aware of the path the blade may take if it slips, and try to stay out of its path.

Blades should always be stored properly when not in use. You should have a storage system to hold all blades that are removed. Disorganized clutter is a quick path to disaster and accidental injury.

While many blades are very strong, you should never use excessive force when manually using a tire trimming blade. Blades are strong, but they are not indestructible. Excessive force may cause the blade to break or fall. If you drop an industrial blade, never try to catch it. It may be instinctive to try to do so, but do your best to avoid this approach, which will almost certainly injure yourself.

It should go without saying, but never engage in any unprofessional hijinks around tire trimming blades. One misstep is enough to turn what should be a fun time into a serious situation you have to deal with.

If a blade is removed from the mechanism it belongs to, never leave it out of sight. For example, never leave objects on top of a blade so that someone could accidentally pick it up without knowing it was there. Blades should always be kept where they are being used or in a safe place for storage.

What Are the Trends and Development Directions of Tire Trimming Blade in the Market

Industry demands

Different tire manufacturers have varying demands for blades. Some require blades with extremely high wear resistance, while others need special tooth profiles to adapt to specific trimming processes. Therefore, providing diversified customized services can better meet customer needs and enhance customer satisfaction.

Customized blade designs

Blades designed for specific automatic tire machines not only improve production efficiency but also significantly reduce downtime. These customized blades optimize overall production efficiency by precisely matching the customer's equipment and production processes.

Optimizing production processes

By gaining an in-depth understanding of customer production processes, blade manufacturers can design blades that better meet customer needs, thereby improving production efficiency and product quality.

Benefits of automation

Automated equipment can significantly improve production efficiency and product consistency while reducing labor costs. Automated trimming blade designs can efficiently complete trimming tasks while ensuring consistent trimming quality for each tire. According to the international tire manufacturing association (ITMA), the application of automated equipment can increase production efficiency by 20% to 30%.

Our Factory

Ganzhou Big Brother Cutting Tools Co., Ltd. is a professional manufacturer and processor of industrial cutting tools. The company team has 15 years of industry experience and has successfully completed technological transformation through years of continuous accumulation and exploration.Also skilled in researching and producing non-standard cutting tools, molds, etc The main products include: packaging machine knives, non-standard blades, industrial knives, food machine knives, woodworking planers, alloy blades, precision knife molds, shredder knives, agricultural machinery knives, and various mechanical cutting tools for mass production and non-standard customization.

FAQ

Q: What is a Tire Trimming Blade?

Q: Why is tire trimming necessary?

Q: What materials are used to make Tire Trimming Blades?

Q: How do Tire Trimming Blades contribute to tire quality?

Q: Can Tire Trimming Blades be customized?

Q: What are the common types of Tire Trimming Blades?

Q: How often do Tire Trimming Blades need to be replaced?

Q: What are the maintenance practices for Tire Trimming Blades?

Q: What safety measures should be taken when using Tire Trimming Blades?

Q: How does the design of a Tire Trimming Blade affect its performance?

Q: Are there any specific blade designs for different tire sizes?

Q: What role does the blade's sharpness play in tire trimming?

Q: How does the blade's material impact its durability and performance?

Q: Can Tire Trimming Blades be used for other applications?

Q: What factors should be considered when choosing a Tire Trimming Blade?

Q: How do advancements in blade technology impact tire manufacturing?

Q: Are there eco-friendly options for Tire Trimming Blades?

Q: What is the cost of Tire Trimming Blades?

Q: Can the performance of Tire Trimming Blades be improved?

Q: Where can I find the best Tire Trimming Blades?