Description

Products Description

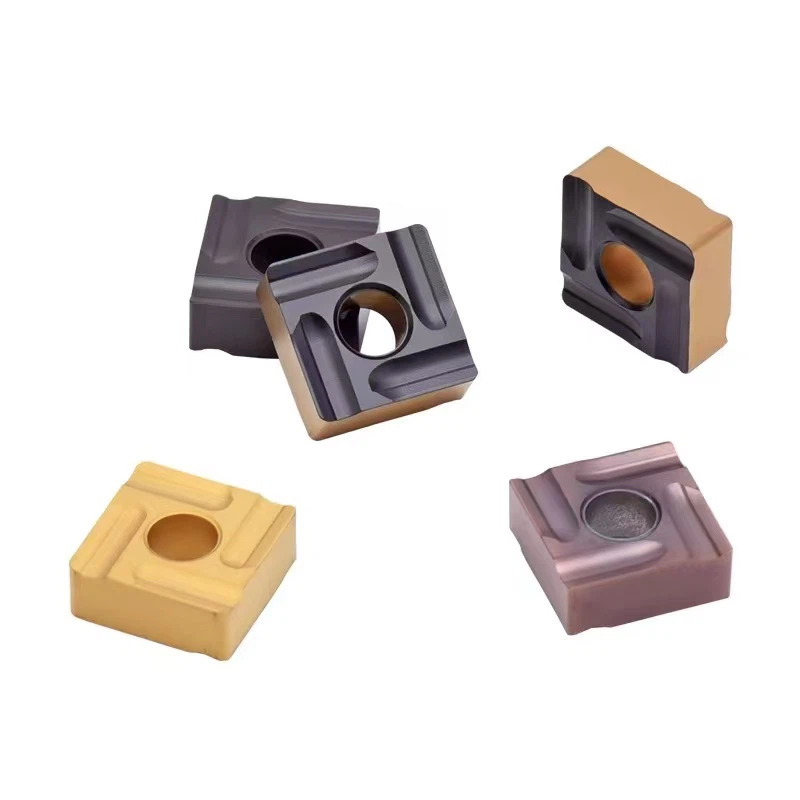

Turning Carbide Inserts are primarily composed of extremely hard tungsten carbide (WC) particles as the base material, bonded together with cobalt using a powder metallurgy process involving sintering under high temperature and pressure. Carbides such as titanium carbide (TiC), tantalum carbide (TaC), and niobium carbide (NbC) are sometimes added to enhance specific properties.

Products Specification

3(1).png image.png

ISO L I.C S d r

DNMG110404-TM 11.60 9.525 4.76 3.81 0.40

DNMG110408-TM 11.60 9.525 4.76 3.81 0.80

DNMG110412-TM 11.60 9.525 4.76 3.81 1.20

DNMG150404-TM 15.50 12.70 4.76 5.16 0.40

DNMG150408-TM 15.50 12.70 4.76 5.16 0.80

DNMG150412-TM 15.50 12.70 4.76 5.16 1.20

DNMG150604-TM 15.50 12.70 6.35 5.16 0.40

DNMG150608-TM 15.50 12.70 6.35 5.16 0.80

DNMG150612-TM 15.50 12.70 6.35 5.16 1.20

Key product structures and features

4b7957d76bdb545d6b5a3ce7a6db5953

Structure Type: Indexable Inserts

Modern turning carbide inserts are almost exclusively indexable inserts. They typically feature polygonal shapes (e.g., triangular, square, rhombic/diamond, round, hexagonal) or specialized geometries.

Multiple Cutting Edges: A single insert usually has multiple identical cutting edges (3, 4, 6, 8, or more).

Indexability: When one cutting edge becomes worn or damaged, the insert can be loosened, indexed (rotated to present a fresh, unused edge), and re-clamped. This significantly increases tool utilization and reduces downtime for tool changes.

Standardization: The insert's shape, size, mounting hole, chip breaker groove, and tip angle adhere to international standards (e.g., ISO), ensuring compatibility and interchangeability with various toolholders/shanks.

Turning Carbide Insert Key Geometric Features:

Rake Angle: The inclination angle of the insert's top face relative to the workpiece. It influences chip formation, cutting forces, and tool strength.

Clearance Angle (Relief Angle): The angle between the insert's flank face and the machined surface. Its primary function is to reduce friction between the flank and the workpiece.

Cutting Edge Inclination Angle (λ): The angle between the main cutting edge and the reference plane. It affects chip flow direction and tip strength.

Lead Angle (Approach Angle - κ): The angle between the projection of the main cutting edge on the reference plane and the feed direction. It influences the ratio of radial to axial forces, as well as chip thickness and width.

Nose Radius: The radius at the junction of the main and auxiliary cutting edges. It affects surface finish, tip strength, and heat dissipation. A larger radius generally improves surface quality and tip strength but increases cutting forces.

Chip Breaker Groove: A precisely ground or pressed groove on the insert's rake face. Its purpose is to control chip curling and breaking, preventing long, tangled chips to ensure operational safety and uninterrupted machining. Chip breaker design is crucial for machining performance.

4591891378b33bbae4cf4af076730761

Application Range:

1. Materials: Widely used for turning various metals, including:

Carbon & Alloy Steels

Stainless Steels

Cast Iron

Superalloys / Heat-Resistant Alloys

Non-ferrous Metals (e.g., Aluminum, Copper alloys - typically using uncoated or specially coated inserts)

Hard Materials (e.g., Hardened Steel)

2. Operations: External turning, internal turning (boring), facing, grooving/cut-off, profiling, threading.

3. Machining Conditions: Ranging from roughing to super-finishing, and from wet machining to dry/hard-MQL (Minimum Quantity Lubrication) high-speed machining.

FAQ

Q: What are your shipping options?

A: We offer various shipping options, including FedEx, DHL and UPS. Shipping cost and delivery time vary based on the destination and the selected shipping method. A tracking number will be provided once your order is shipped for you to track your delivery.

Q: Can I get technical support for tool usage?

A: Absolutely, our team of experts is available to assist with technical support and guidance on tool applications.

Q: What is Foreign Trade-Express?