Description

Product introduction

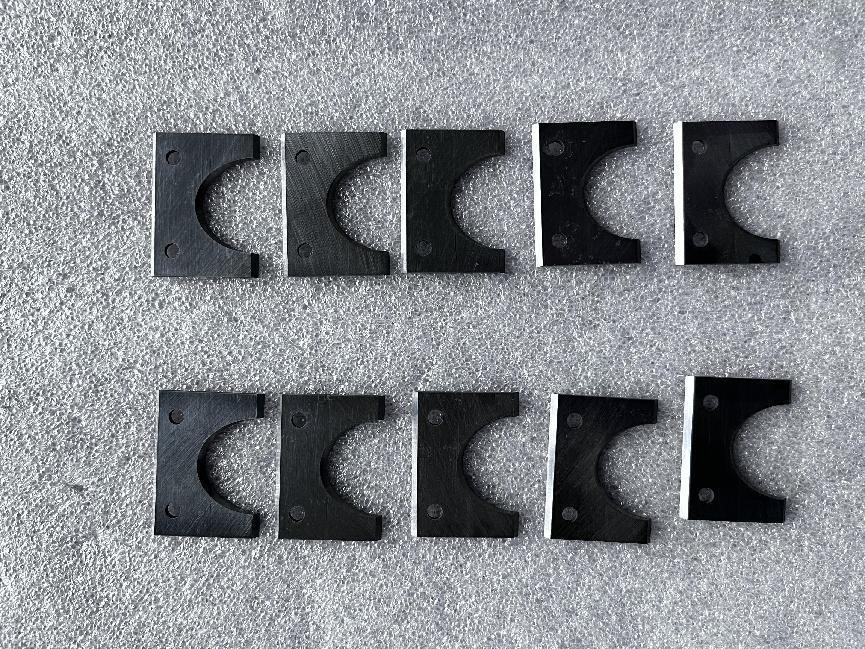

Woodworking forming blades are key tools used in wood processing, especially in wood cutting, profiling, trimming and other links. When in use, woodworking profiling blades are usually installed on the tool holder of woodworking equipment and cut wood by high-speed rotation.

Product features

High Hardness

Our woodworking forming blades are made of high-carbon tool steel, and its hardness reaches HRC 62-64, which is 15-20% higher than ordinary carbon steel planer blades (usually HRC 52-56). This high hardness makes the blade less likely to bend and deform during work. Under a lateral pressure of 300N, our blade deflects no more than 0.05mm, while ordinary blades may deflect up to 0.2mm.

Durability

After cutting red oak (density about 0.75 g/cm³) for 8 hours continuously, our blade only lost 0.02mm thickness, while ordinary blades lost 0.08mm. This durability greatly reduces the frequency of blade replacement, which not only saves material costs, but also reduces downtime caused by blade replacement and improves overall work efficiency.

Thermal Stability

After our woodworking forming blades have been working continuously for 10 hours at a high temperature of 350°C, the hardness and sharpness of the blades will not decrease by more than 3%. In contrast, the hardness of common woodworking blades on the market will drop significantly by 20-25% after working at 250°C for 6 hours, which seriously affects the cutting quality and efficiency.

FAQ

Q: Can you provide samples? Are the samples free?

Q:What is the delivery time?

Q: What payment terms do you have?

Q: Would you accept using our logo?

Q: What are the shipping options?