Description

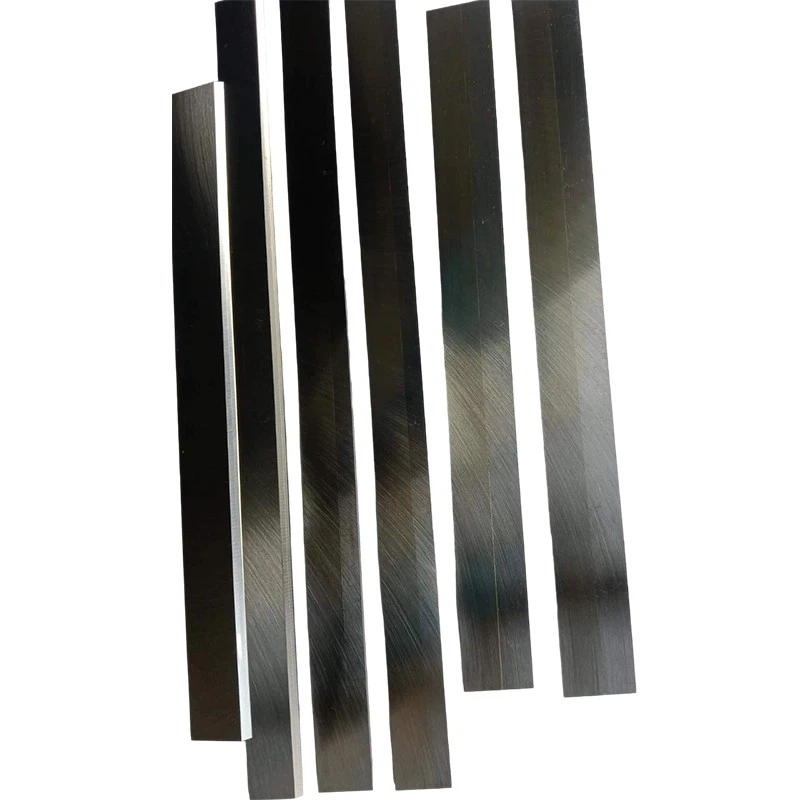

Product Introduction

Woodworking steel planer blade is one of the important tools used for wood processing. It needs to be installed on the planer to cut and trim the wood surface.

Product features

High Hardness

Our woodworking steel planer blade is made of high-carbon tool steel, which has a hardness of HRC 62-64, 15-20% higher than ordinary carbon steel planer blades (usually HRC 52-56). This high hardness makes the blade less likely to bend and deform during work. Under a lateral pressure of 300N, our blade deflects no more than 0.05mm, while ordinary blades may deflect up to 0.2mm.

Durability

After cutting red oak (density about 0.75 g/cm³) for 8 hours, our blade only lost 0.02mm of thickness, while ordinary blades lost 0.08mm. This means that our blade can stay sharp for 4 times longer than ordinary blades. This durability greatly reduces the frequency of blade replacement, which not only saves material costs, but also reduces downtime caused by blade replacement and improves overall work efficiency.

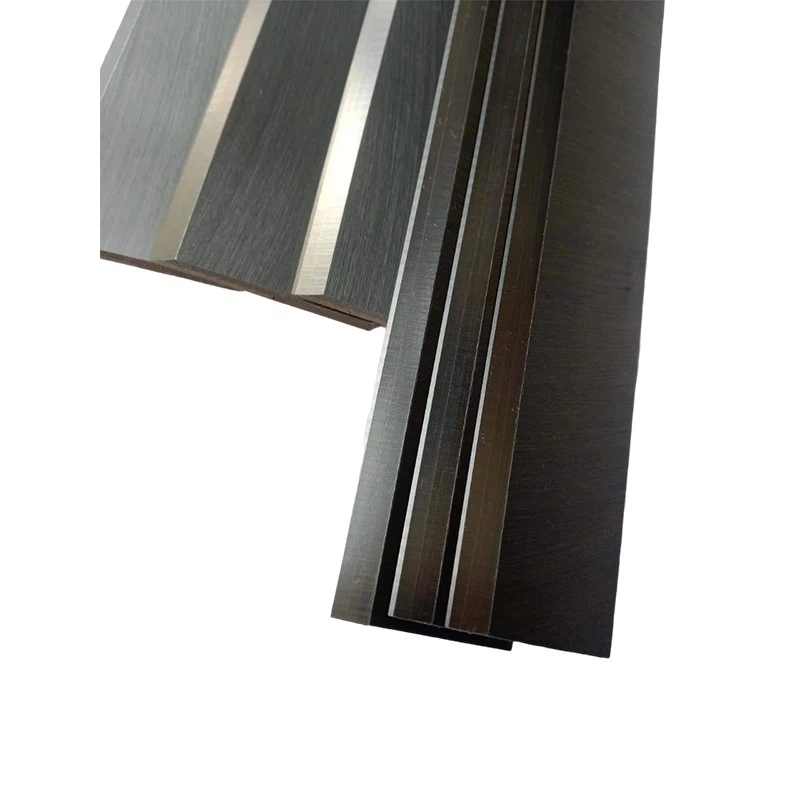

Precision Cutting Edge

Using CNC grinding technology, we precisely process the cutting edge of the woodworking steel planer blade to an angle of 25°±0.5°, and the straightness error of the cutting edge is controlled within ±0.005mm. This makes the force of the cutting edge in contact with the wood more uniform during cutting, thereby reducing the friction and resistance generated during the cutting process by 23%. The reduction in cutting resistance can not only reduce the wear and heat of the blade, but also improve the cutting efficiency and cutting surface quality.

Strong Corrosion Resistance

The surface of the woodworking steel planer blade adopts a 15μm thick nano-scale TiAlN coating. In a 500-hour salt spray test (ASTM B117 standard), the corrosion area does not exceed 1%, while the corrosion area of the uncoated blade reaches 15%. This corrosion resistance ensures that our blades will not rust even if they are used continuously for 30 days in an environment with a relative humidity of 90%, greatly extending the service life of the blades in various climatic conditions.

FAQ

Q: Are you a trading company or a manufacturer?

Q: What is your delivery time?

Q: Do you provide samples? Are they free or do they come at an additional cost?

Q: What are your terms of payment?